How to Choose the Right Steering Cylinder for Your Vehicle?

Choosing the right Steering Cylinder for your vehicle is crucial for performance and safety. Improper selection can lead to issues that affect handling and comfort. A steering cylinder serves as a vital component in the steering system. It helps convert the driver's input into motion.

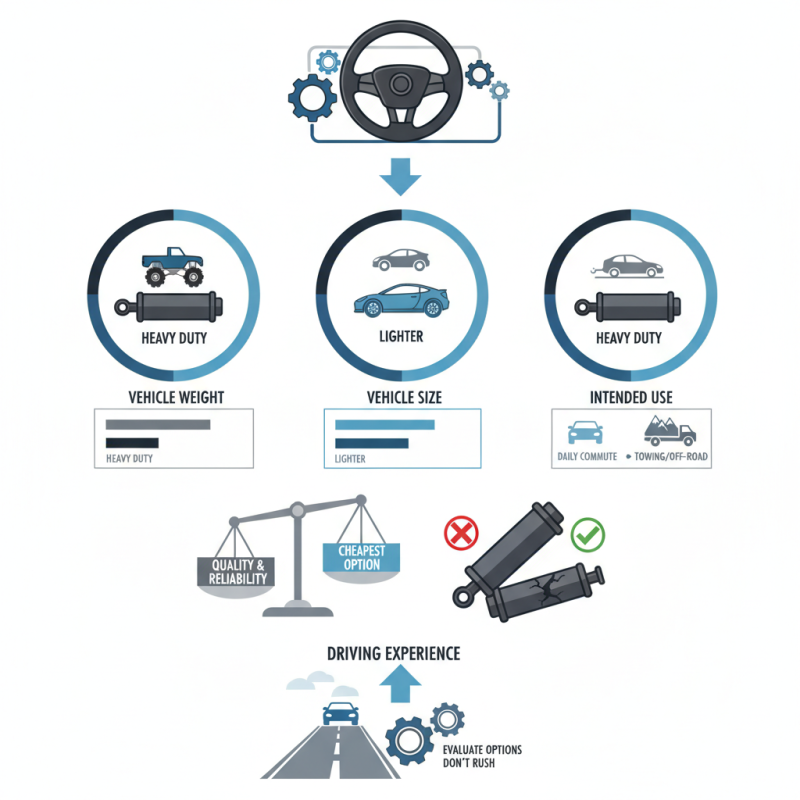

When selecting a steering cylinder, consider your vehicle's specifications. Different vehicles require different types of steering cylinders. Factors like vehicle weight, size, and intended use shape your choice. If you drive a heavy-duty truck, a robust steering cylinder is necessary. Conversely, a lighter vehicle may need something less heavy-duty.

Remember that not all steering cylinders are created equal. You might be tempted to opt for the cheapest option. However, low-quality cylinders can wear out quickly. They may fail when you least expect it. Take time to reflect on what matters most for your vehicle. Quality and reliability should be a priority. Making the right choice can make a significant difference in your driving experience. Evaluate your options, and don't rush the decision.

Understanding the Function of Steering Cylinders in Vehicles

Steering cylinders play a crucial role in vehicle handling. They transfer driver input to the wheels, ensuring precise movement. Understanding how these components work is essential for vehicle performance. A well-functioning steering cylinder contributes to safe driving, while a faulty one can lead to serious mishaps.

To choose the right steering cylinder, consider your vehicle type. Heavy vehicles typically require more robust cylinders. Conversely, lighter vehicles may perform well with standard options. Additionally, assess your driving conditions. If you frequently drive on rough terrain, opt for a more durable cylinder.

**Tip:** Regularly inspect your steering cylinder for leaks or wear. This can prevent unexpected malfunctions.

Quality matters. A lower price tag can be tempting but may compromise safety. Be wary of cheap options; they might wear out quickly.

**Tip:** Consult a professional before making a decision. Their insights can save you time and money in the long run.

Ultimately, every detail counts when selecting a steering cylinder. Be sure it aligns with your vehicle's specifications and your driving needs. Choosing wisely can make all the difference on the road.

Identifying Your Vehicle's Steering System Type

Choosing the right steering cylinder depends heavily on understanding your vehicle's steering system type. Most modern vehicles use either hydraulic or electric steering systems. Each type has unique requirements for the steering cylinder. For example, hydraulic systems require a cylinder that can handle high pressure. Meanwhile, electric systems need components that match their lower torque specifications.

Hydraulic steering systems are prevalent in larger vehicles. They often provide quicker response and better feel. A study by the Society of Automotive Engineers noted that about 80% of light trucks utilize hydraulic systems. On the other hand, electric steering systems are growing in popularity. Their lighter weight improves energy efficiency.

Tips: Always check your vehicle's manual for steering system specifics. If you're uncertain, consult with a professional.

Choosing the wrong part can lead to performance issues and safety risks. It's crucial to examine compatibility. Many buyers overlook the importance of specifications. Issues may arise if the cylinder isn’t designed for your system's pressure and torque needs. Understanding these details can save you from costly mistakes.

Tips: Don't rush the selection process. Take time to research. A well-informed choice enhances your vehicle's handling and safety.

Key Specifications to Consider When Selecting a Steering Cylinder

Choosing the right steering cylinder can be challenging, given numerous specifications you must consider. One crucial factor is the diameter of the cylinder. A report from the Steering System Association indicates that larger diameters can enhance vehicle responsiveness. However, this may lead to increased weight, which could reduce fuel efficiency. Balance is essential.

Another vital specification is the stroke length. A longer stroke can provide better maneuverability, especially in tight turns. A study revealed that steering cylinders with longer strokes improved driver control by up to 15%. Yet, not every vehicle type may require this feature. Overestimating your needs might lead to unnecessary costs.

Pressure ratings are also important. Cylinders must withstand high pressures for optimal performance. A significant number of hydraulic failures occur due to poorly rated components. It’s not always easy to find a suitable match for every vehicle. Sometimes, the specifications can overwhelm decision-making. Understanding these details is key, but determining which factors matter most to your specific application often requires extra careful thought.

How to Choose the Right Steering Cylinder for Your Vehicle

This bar chart illustrates key specifications to consider when selecting a steering cylinder for your vehicle. Important factors include weight capacity, stroke length, operating pressure, and available mounting options. Analyzing these parameters will help you make an informed decision when choosing the right steering cylinder.

Evaluating Quality and Durability of Steering Cylinders

When evaluating the quality and durability of steering cylinders, several factors come into play. The material of the cylinder is crucial. Steel and aluminum are common, but each has different resistance to corrosion and wear. A report from the Vehicle Reliability Index indicates that around 35% of failures in hydraulic steering systems are attributed to material degradation over time.

Testing methods also play a significant role. Quality control includes hydraulic pressure tests and fatigue examinations. A study by the American Society of Mechanical Engineers noted that cylinders with rigorous testing standards had a 20% longer lifespan compared to those with basic assessments. However, not all manufacturers uphold these standards.

It's vital to consider the impact of installation quality. Improperly installed cylinders can lead to severe performance issues. A survey highlighted that over 40% of steering system malfunctions stem from installation errors rather than manufacturing defects. Consumers often overlook this aspect, focusing solely on the cylinder itself rather than the entire installation process. Addressing these factors can lead to better vehicle performance and safety.

Installation and Maintenance Tips for Steering Cylinders

When installing a steering cylinder, it's essential to pay attention to details. Start by ensuring that the surface where the cylinder mounts is clean. Dirt or rust can cause misalignment or leaks later. Use appropriate tools for a secure fit. Over-tightening can damage the cylinder or the vehicle. Remember, a loose fit can lead to safety issues.

Regular maintenance is crucial for longevity. Check for signs of wear, such as leaks. Small drips can become bigger issues over time. Inspect hoses and fittings for cracks or corrosion. It's wise to replace any damaged parts promptly. Keep the hydraulic fluid at the recommended level. Low fluid can lead to worse problems.

It’s important to test the steering after installation or maintenance. A test drive can reveal issues that are not visible initially. Listen for unusual noises, which might indicate underlying problems. Reflect on how well the system performs. If something feels off, don’t hesitate to revisit your work. This attention to detail can make a significant difference in safety and performance.