Exploring Diverse Features and Applications of the Best New Hydraulic Cylinder Models

In today's rapidly evolving industrial landscape, the demand for efficient and reliable machinery is ever-increasing, and at the heart of this innovation lies the New Hydraulic Cylinder. Originating from top-notch factories in China, these cutting-edge models are not only revolutionizing various applications but are also becoming a benchmark of global trust and performance. With advancements in technology, the latest hydraulic cylinders offer diverse features that cater to a variety of sectors, including manufacturing, construction, and agriculture. This blog delves into the remarkable attributes of the best new hydraulic cylinder models, exploring their versatility and the ways in which they are enhancing productivity and safety in numerous applications. Join us as we unpack these innovations that are setting new standards in hydraulic engineering.

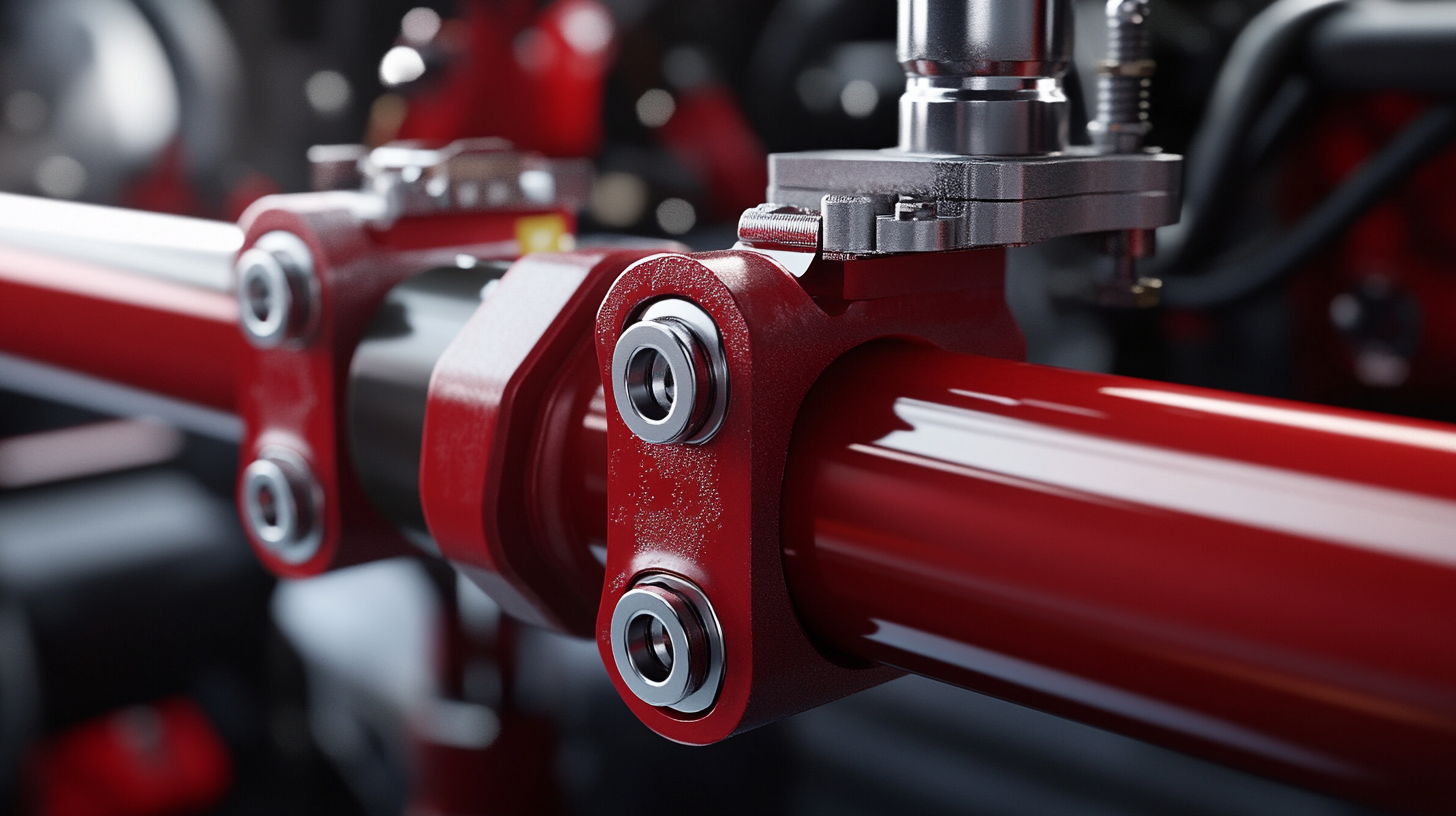

Understanding Hydraulic Cylinder Types and Their Industrial Applications

Hydraulic cylinders are crucial components in various industrial applications, offering smooth and efficient motion for heavy machinery and equipment. Understanding the different types of hydraulic cylinders—such as double-acting, single-acting, and telescopic cylinders—can significantly influence the selection process based on specific operational needs. As industries evolve, the demand for custom hydraulic solutions is on the rise, leading to innovative designs that enhance performance and reduce operational costs.

Hydraulic cylinders are crucial components in various industrial applications, offering smooth and efficient motion for heavy machinery and equipment. Understanding the different types of hydraulic cylinders—such as double-acting, single-acting, and telescopic cylinders—can significantly influence the selection process based on specific operational needs. As industries evolve, the demand for custom hydraulic solutions is on the rise, leading to innovative designs that enhance performance and reduce operational costs.

The global market for hydraulic cylinders is anticipated to witness substantial growth, projected to reach $18.3 billion by 2027. This growth is driven by advancements in industrial automation, where hydraulic systems play a vital role in enhancing productivity and efficiency. Sectors like manufacturing, construction, and forestry are increasingly relying on hydraulic cylinders to execute repetitive tasks with precision, enabling greater mechanization and reliability in operations. As technology continues to advance, the integration of smart hydraulic systems is likely to open new avenues for enhanced functionality across diverse industrial applications.

Key Features of the Latest Hydraulic Cylinder Models

When exploring the latest hydraulic cylinder models, several key features stand out that significantly enhance performance across various engineering applications. One of the most notable advancements is the integration of high precision monitoring techniques, which allow for real-time assessment of hydraulic column stress. This development is particularly crucial in heavy industries, such as coal mining, where the reliability of support systems is vital. Precision monitoring helps to ensure that cylinders maintain optimal performance under varying loads, improving both safety and efficiency.

Additionally, modern hydraulic systems are increasingly utilizing sophisticated modeling approaches, such as the bond graph method. This technique aids in analyzing the internal dynamics of hydraulic cylinders, including aspects like internal leakage and dynamic responsiveness. Furthermore, these models not only support the design of more efficient hydraulic systems but also enhance the theoretical understanding of performance metrics, like maximum digging resistance in excavator applications. As technology continues to advance, the features found in new hydraulic cylinder models will undoubtedly evolve, offering innovative solutions to meet the demands of diverse engineering fields.

Import and Export Certifications for Hydraulic Cylinders: What You Need to Know

When dealing with hydraulic cylinders, understanding import and export certifications is crucial for ensuring compliance with international trade regulations. These certifications not only guarantee that the hydraulic cylinders meet safety and quality standards but also facilitate smoother transactions across borders. Before engaging in any trade, businesses should familiarize themselves with the specific certification requirements of their target markets. This knowledge can help avoid potential legal issues and delays in shipping.

**Tip:** Always check with local regulatory bodies to stay updated on the necessary certifications required for hydraulic cylinders in your region. This proactive approach can save time and resources in the long run.

Additionally, businesses should consider the certifications that enhance their product's credibility, such as ISO or CE marks. These certifications can significantly improve a company's reputation and open doors to new markets. When exporting, ensuring that all documentation is complete and accurate is essential to prevent customs issues.

**Tip:** Maintain a comprehensive checklist of all required certifications and documents to streamline the export process. This practice can help minimize errors and ensure compliance with both domestic and international regulations.

Best Practices for Selecting the Right Hydraulic Cylinder for Your Project

When selecting the right hydraulic cylinder for your project, it's essential to consider several factors that can significantly impact performance and efficiency. According to a report by MarketsandMarkets, the global hydraulic cylinder market is expected to grow from $12.3 billion in 2020 to $15.7 billion by 2025, driven by the increasing demand in construction and manufacturing sectors. This demand underscores the importance of choosing the correct specifications to ensure that your hydraulic system operates at optimal performance levels.

One of the best practices is to evaluate the application requirements, including load capacity, stroke length, and environmental conditions. For instance, a study by ResearchAndMarkets highlights that cylinders used in extreme temperatures require specialized materials to withstand thermal expansion and contraction without losing functionality. Additionally, attention should be paid to the cylinder’s mounting style, as improper mounting can lead to premature wear and system failure. By understanding the unique demands of your project and utilizing industry insights, you can make informed decisions that enhance the longevity and effectiveness of your hydraulic systems.

Innovative Technologies in Hydraulic Cylinder Design and Performance

The landscape of hydraulic cylinder design is evolving rapidly due to innovative technologies that enhance performance and efficiency. Recent reports indicate that the global hydraulic cylinder market is projected to reach USD 17.8 billion by 2027, driven by advancements in materials and manufacturing processes. New models are increasingly incorporating smart technologies, such as sensors for real-time performance monitoring and predictive maintenance capabilities, which not only optimize functionality but also reduce downtime.

The landscape of hydraulic cylinder design is evolving rapidly due to innovative technologies that enhance performance and efficiency. Recent reports indicate that the global hydraulic cylinder market is projected to reach USD 17.8 billion by 2027, driven by advancements in materials and manufacturing processes. New models are increasingly incorporating smart technologies, such as sensors for real-time performance monitoring and predictive maintenance capabilities, which not only optimize functionality but also reduce downtime.

In addition to smart technologies, the latest hydraulic cylinders are utilizing advanced materials that offer greater durability and weight reduction. Adoption of lightweight composite materials can reduce the overall equipment weight by up to 30%, enhancing energy efficiency during operations. Tips for choosing the right hydraulic cylinder include assessing the specific application requirements, considering the operating environment, and determining compatibility with existing machinery to maximize performance.

Another crucial aspect in hydraulic cylinder advancements involves energy efficiency. Studies show that hydraulic systems, when optimized with new designs, can achieve energy savings of up to 25%. This encourages users to invest in updated models that not only meet current industry standards but also support sustainability goals. When upgrading, evaluate cylinders that offer improved seal designs and internal geometries to minimize hydraulic losses, ensuring that your equipment operates at peak efficiency.