Exploring Innovative Alternatives to the Best High Pressure Hydraulic Cylinders for Enhanced Efficiency

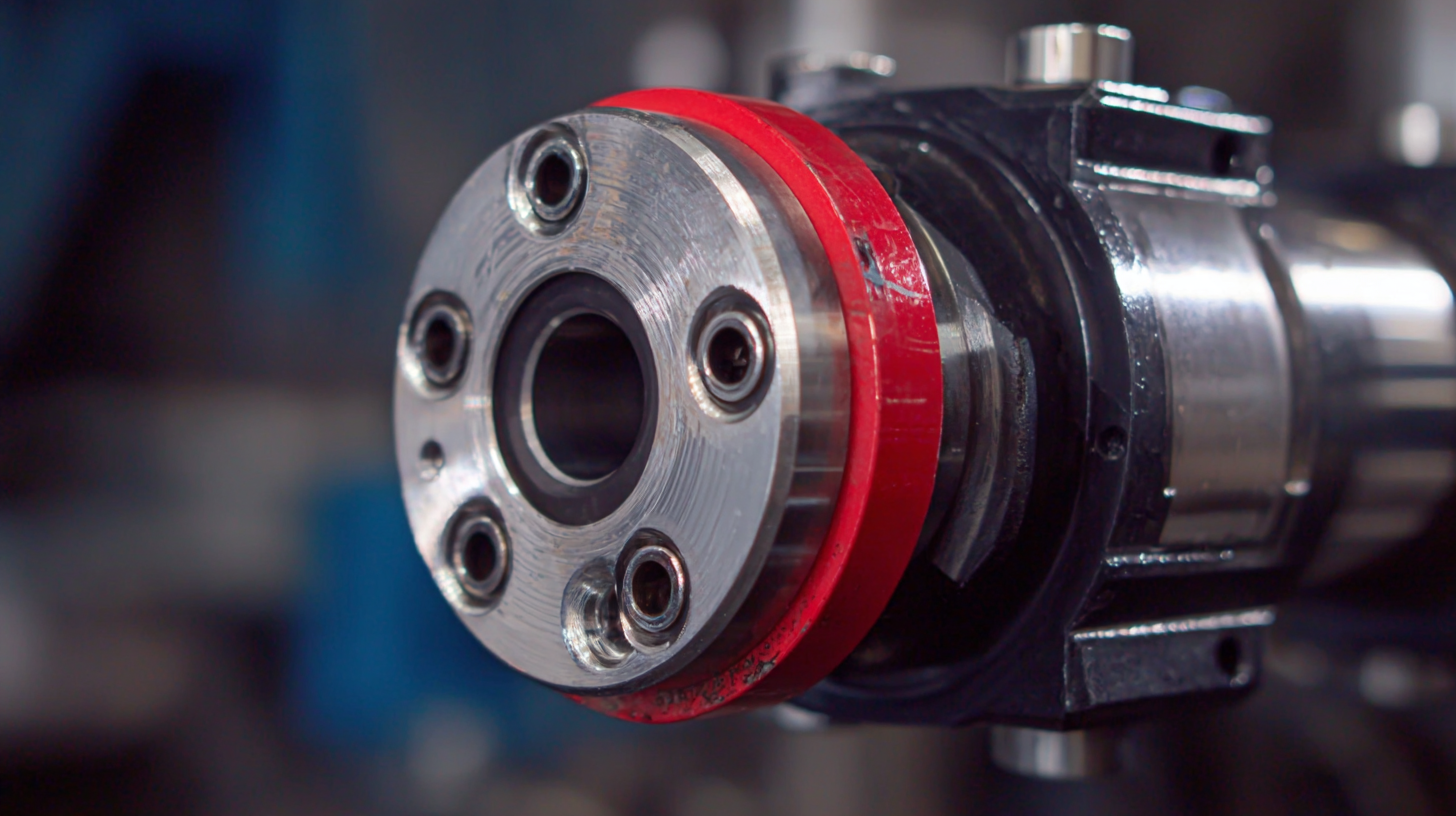

In today's fast-paced industrial landscape, the demand for robust and efficient machinery is more critical than ever. Among these essential components, the High Pressure Hydraulic Cylinder stands out as a vital element that drives various applications, from heavy machinery to precision tools. As industries strive for enhanced efficiency and performance, the exploration of innovative alternatives to conventional hydraulic cylinders becomes paramount.

This blog delves into the latest advancements and alternatives that promise to elevate the performance of High Pressure Hydraulic Cylinders, emphasizing the importance of quality and reliability in manufacturing. With China's commitment to producing high-quality hydraulic solutions that meet global standards, we will explore how these innovations not only improve operational efficiency but also contribute to sustainability in industrial practices, ensuring that manufacturers worldwide can trust in these advancements for their needs.

Innovative Technologies Reshaping High Pressure Hydraulic Cylinder Efficiency

The integration of innovative technologies is revolutionizing the efficiency of

high pressure hydraulic cylinders, which are crucial in various applications

from manufacturing to automotive industries. Advanced materials, such as lightweight composites

and coatings, are being utilized to enhance durability while reducing weight. Additionally, digital

monitoring systems are being incorporated to provide real-time data on performance and maintenance needs, allowing for

proactive management that minimizes downtime.

Tip: Consider investing in hydraulic cylinders that come equipped with

smart technology features. This can significantly improve operational

efficiency by offering insights into performance and helping to predict potential failures before they occur.

Moreover, the emergence of eco-friendly hydraulic fluids is reshaping

the market, contributing to sustainability while maintaining high operational standards.

These fluids not only reduce environmental impact but can also enhance the performance of hydraulic systems by providing

better lubrication and reducing wear.

Tip: When choosing hydraulic systems, explore options with eco-friendly

fluids to not only meet regulatory requirements but also boost system performance and longevity.

Comparative Analysis of Traditional vs. Alternative Cylinder Designs

In the quest for enhanced efficiency in hydraulic systems, a comparative analysis between traditional and alternative cylinder designs reveals significant innovations. Traditional high-pressure hydraulic cylinders, while reliable, can present limitations in weight and energy efficiency. They often rely on heavy materials and conventional designs, which may restrict mobility and adaptability in various applications.

In contrast, alternative designs, such as self-contained electro-hydraulic cylinders, offer a more streamlined approach. These systems can reduce energy consumption by integrating electric components directly into the hydraulic mechanism, providing more precise control and improved responsiveness.

Furthermore, advancements in materials science, particularly with Fibre Reinforced Polymers (FRPs), provide opportunities to enhance the strength-to-weight ratio of hydraulic cylinders. By turning to alternative materials, engineers can achieve similar or superior performance while minimizing the overall weight. This transformation in design and materials not only leads to better energy efficiency but also aligns with modern sustainability goals. As the landscape of hydraulic technology evolves, exploring these innovative alternatives becomes essential for industries aiming to enhance performance while reducing their environmental footprint.

Cost-Benefit Examination of Enhanced Hydraulic Systems for Various Industries

As industries increasingly seek efficiency and profitability, the evaluation of high-pressure hydraulic systems has come to the forefront. Recent reports suggest that upgraded hydraulic technologies can improve operational efficiency by up to 25%, translating to significant cost savings. For instance, a comprehensive study by the International Fluid Power Society indicates that businesses implementing advanced hydraulic systems have reported reduced maintenance costs by approximately 15-20%, which is crucial for industries such as manufacturing, automotive, and construction.

**Tip:** Consider conducting a cost-benefit analysis tailored to your specific applications. Factor in not just initial investment costs but also long-term savings from improved efficiency and decreased downtime.

Furthermore, the performance metrics of enhanced hydraulic systems not only reflect immediate savings but also contribute to sustainability goals. According to a 2022 report by the Hydraulic Institute, integrating innovative alternatives into hydraulic systems has been shown to reduce energy consumption by around 30%, helping companies meet regulatory standards and improve their environmental footprint.

**Tip:** Evaluate supplier offerings that prioritize sustainable materials and design; such choices can lower operational costs while enhancing your brand's reputation in environmentally-sensitive markets.

Efficiency Comparison of Innovative Hydraulic Cylinder Alternatives

This chart compares the efficiency of traditional hydraulic cylinders versus innovative alternatives across different industries, highlighting their cost-benefit ratios.

Case Studies: Successful Implementation of Innovative Hydraulic Solutions

In the quest for enhancing operational efficiency within the manufacturing sector, innovative hydraulic solutions have emerged as a vital trend, especially when addressing the performance of high-pressure hydraulic cylinders. Recent reports indicate that the global hydraulic cylinder market is expected to reach approximately $21 billion by 2025, driven by advancements in technology and the rising demand for automation across various industries. Companies embracing these innovations have recorded substantial improvements in productivity and energy efficiency, effectively positioning themselves as leaders in a highly competitive landscape.

Case studies in regions like Hunan, where the Ministry of Industry and Information Technology recently highlighted exemplary cases of reliability enhancement, showcase the successful integration of innovative hydraulic systems. Among those recognized, two cases demonstrate how modern hydraulic technologies have facilitated significant enhancements in operational processes. Such implementations not only improve the durability and efficiency of hydraulic cylinders but also contribute to increased reliability within manufacturing systems. As companies strive for excellence, these innovative hydraulic solutions serve as a pivotal factor in driving future industrial advancements.

Future Trends and Predictions for Hydraulic Cylinder Developments in 2024

The hydraulic cylinder market is anticipated to experience significant growth in the coming years, with projections indicating a revenue increase from USD 14.3 billion in 2021 to USD 18.3 billion by 2027. This expansion translates to a robust compound annual growth rate (CAGR), driven by increasing demand in various sectors, including construction, agriculture, and manufacturing. Despite the encroaching presence of electronic alternatives, the hydraulic industry maintains a positive outlook, underscoring its integral role in fluid power applications.

As industries navigate economic uncertainties in early 2024, the hydraulic sector is expected to rebound with renewed vigor, particularly in mobile hydraulics. According to market analyses, a return to growth is projected for 2025, signaling a recovery phase for hydraulic systems. In Australia, the hydraulic cylinder and system market is forecasted to expand at a CAGR of 3.8% over the next decade, reflecting a sustained investment in hydraulic technologies that facilitate operational efficiency and productivity. This trend indicates a resilience in the hydraulic market, emphasizing innovation as key to maintaining competitiveness amid evolving industry dynamics.