The Future of Hyd Cylinder Repair: Innovations Leading to Industry Efficiency Gains

The landscape of Hyd Cylinder Repair is undergoing a significant transformation, driven by technological innovations that promise to enhance efficiency across various industries. According to a recent report by MarketsandMarkets, the global hydraulic cylinder market is projected to reach $16.8 billion by 2027, highlighting the critical role that maintenance and repair play in maximizing equipment lifespan and operational productivity. With a rising demand for sustainable practices and increased automation, companies are increasingly adopting advanced diagnostic tools and predictive maintenance strategies, which not only minimize downtime but also reduce repair costs. This blog will explore the latest innovations in Hyd Cylinder Repair, including the integration of IoT technologies, advanced materials, and data analytics, all aimed at streamlining operations and driving industry efficiency gains.

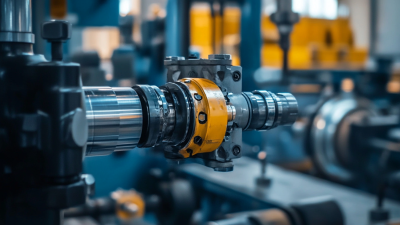

Innovative Technologies Transforming Hydraulic Cylinder Repair Practices

In the rapidly evolving landscape of hydraulic cylinder repair, innovative technologies are transforming industry practices and enhancing overall efficiency. Advances in techniques such as predictive maintenance, real-time monitoring, and advanced material science are playing pivotal roles in streamlining repair processes. These technologies not only reduce downtime but also ensure that hydraulic cylinders operate at peak performance for extended periods, much like the structures equipped with modern earthquake-resistant technologies designed to bend but not break.

As we embrace these innovations, it’s essential to implement best practices for optimal results. First, consider integrating predictive analytics into your maintenance program. By leveraging data to anticipate potential failures, you can schedule repairs before critical issues arise, minimizing disruptions. Second, invest in training your technicians on the latest repair technologies to ensure they are equipped with the necessary skills and knowledge. Lastly, keep an eye on materials developments; using advanced coatings and composites can significantly enhance component lifespan and performance.

Hydraulic cylinder repair is on a transformative path, with innovations paving the way for efficiency gains that parallel advancements seen in other industries, such as earthquake-resistant construction. By adopting these innovative approaches, businesses can significantly enhance their operational reliability and longevity.

The Role of Predictive Maintenance in Enhancing Repair Efficiency

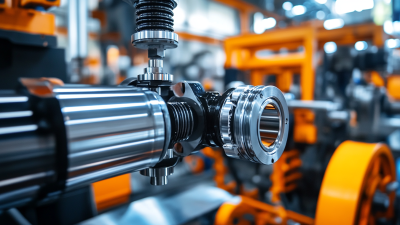

Predictive maintenance has emerged as a cornerstone in enhancing the efficiency of hydraulic cylinder repair. By leveraging advanced data analytics and monitoring technologies, industries can now anticipate potential failures before they occur. This proactive approach allows maintenance teams to schedule repairs during non-peak hours, minimizing downtime and reducing the overall cost associated with unexpected breakdowns. Not only does this lead to smoother operations, but it also extends the lifespan of hydraulic equipment, ultimately enhancing productivity.

Incorporating predictive maintenance involves the use of sensors and IoT devices that continuously track the condition of hydraulic cylinders. These technologies provide real-time data on factors such as pressure, temperature, and wear. With this information, companies can implement tailored maintenance schedules that focus on specific needs rather than generic timelines. This targeted strategy ensures that repairs are completed efficiently, and resources are utilized effectively, marking a significant shift towards smarter, data-driven operational practices. The integration of predictive maintenance represents a vital transformation in the hydraulic repair industry, driving significant efficiency gains while fortifying equipment reliability.

The Future of Hyd Cylinder Repair: Innovations Leading to Industry Efficiency Gains

| Innovation | Description | Efficiency Gain (%) | Implementation Time (months) | Predictive Maintenance Role |

|---|---|---|---|---|

| IoT Sensors | Integration of sensors to monitor cylinder health in real-time. | 30% | 6 | Allows early detection of issues, reducing repair time. |

| AI-Powered Analytics | Using machine learning algorithms to predict failures. | 40% | 4 | Enhances decision-making for repair schedules. |

| Remote Monitoring | Monitoring cylinder performance from a distance. | 25% | 3 | Reduces the need for onsite inspections. |

| Augmented Reality (AR) Assistance | Using AR for remote support during repairs. | 20% | 5 | Improves training and troubleshooting efficiency. |

| Wearable Tech for Technicians | Providing technicians with smart wearables for real-time data. | 15% | 2 | Enhances worker safety and efficiency. |

Comparative Analysis of Traditional vs. Modern Repair Techniques

The repair techniques for hydraulic cylinders are evolving, driven by technological advancements that enhance efficiency and reliability. Traditional methods often involve lengthy inspection and manual repairs that can lead to extended downtime. In contrast, modern techniques leverage real-time monitoring and predictive maintenance, significantly reducing the time and resources required for repairs. With the integration of advanced diagnostic tools, technicians can now conduct comprehensive evaluations with greater accuracy, identifying potential issues before they escalate.

A comparative analysis reveals that modern repair techniques not only speed up the process but also improve overall operational efficiency. The adoption of remote diagnostics allows for quicker turnaround times, enabling businesses to minimize equipment failure and maintenance costs. Fleet operators, who increasingly rely on hydraulic systems, benefit from these innovations by maintaining higher levels of uptime and reliability in their operations. As the industry moves forward, the integration of these advanced repair techniques represents a significant shift toward more efficient, data-driven maintenance practices.

The Impact of Automation on Repair Turnaround Times

The repair of hydraulic cylinders has been fundamentally transformed by automation, significantly improving turnaround times within the industry. According to a recent report by the Hydraulic Repair Association, automation technologies have cut repair cycles by up to 30%, allowing businesses to reallocate resources and reduce downtime. With advanced machinery and robotic systems handling disassembly and assembly functions, technicians can focus on more intricate diagnosis and repair tasks, ultimately increasing overall workplace efficiency.

Tip: To maximize the benefits of automation in your repairs, consider investing in training programs for your staff to seamlessly work alongside automated systems. This will ensure that your team is not only skilled in traditional repair methods but is also adept at operating new technologies.

The integration of data analytics further complements automation by providing real-time insights into repair processes. A study from the Institute of Hydraulic Research indicates that companies employing data analytics in their repair operations have reported a 25% reduction in unexpected failures. This shift allows for predictive maintenance, where potential issues are identified before they escalate, thereby enhancing reliability and performance.

Tip: Implement regular reviews of your data analytics outputs to refine your repair processes continually. Engaging in this practice can help you stay ahead of potential issues, ensuring that your operations remain efficient and effective.

The Future of Hyd Cylinder Repair: Innovations Leading to Industry Efficiency Gains

Case Studies Highlighting Successful Innovations in Repair Processes

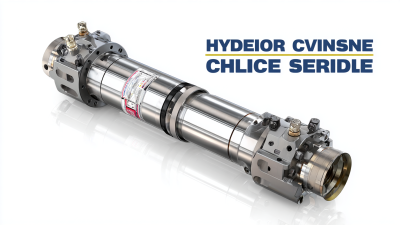

The landscape of hydraulic cylinder repair is rapidly evolving, driven by innovative techniques and technologies that enhance efficiency and effectiveness. One notable case study involves a leading repair facility that adopted diagnostic technology to streamline their processes. By implementing advanced sensing devices, technicians can now accurately identify issues within hydraulic cylinders without the need for complete disassembly. This not only reduces downtime but also lowers repair costs significantly, showcasing how innovation can translate into tangible benefits for the industry.

Another compelling example comes from a company that integrated robotic automation into their repair workflows. By allowing robots to handle repetitive tasks such as cleaning and assembly, human technicians can focus on more complex diagnostics and repairs. This shift has resulted in faster turnaround times and improved precision. Moreover, the use of data analytics helps track repair trends and operational efficiencies, fostering a culture of continuous improvement within the organization. These successful implementations highlight how embracing cutting-edge technologies can revolutionize hydraulic cylinder repair, making it more efficient and responsive to customer needs.

Related Posts

-

Innovative Strategies for Effective Hydraulic Cylinder Maintenance and Repair Solutions

-

2025 Insights: Essential Checklist for Global Buyers on Hydraulic Cylinder Repair Innovations

-

Navigating the 2025 Tech Landscape: A Comprehensive Checklist for Optimal Hydraulic Cylinder Service

-

Finding Quality Suppliers for Best Hydraulic Cylinder Repair Solutions

-

Understanding Industry Standards: How to Choose the Best Hydraulic Cylinder Service for Your Needs

-

Exploring the Varieties and Applications of Hydraulic Pistons in Modern Industries