The Path Ahead for Hydraulic Seals in a Rapidly Evolving Market

In today's fast-paced industrial landscape, the demand for reliable and efficient components is more critical than ever, and hydraulic seals are at the forefront of this evolution. These crucial components ensure operational efficiency and longevity in various applications, from heavy machinery to aerospace technology. As industries continue to innovate and adapt to new technologies, the role of hydraulic seals is undergoing significant transformation. Emerging trends such as automation, sustainability, and advanced materials are reshaping the market dynamics, presenting both challenges and opportunities for manufacturers and users alike. In this blog, we will explore the current state of hydraulic seals, the factors driving changes in the market, and the path ahead for these integral components as they strive to meet the growing demands of an ever-evolving sector.

Current Trends Influencing the Hydraulic Seals Market Dynamics

The hydraulic seals market is experiencing significant transformations, driven by advancements in technology and shifting market demands. One of the key current trends is the growing integration of mobile hydraulic equipment across diverse applications, which necessitates more reliable and efficient sealing solutions. As industries increasingly adopt automation and smart technologies, hydraulic seals must evolve to meet new performance standards. This evolution not only enhances the durability and longevity of hydraulic systems but also contributes to overall operational efficiency.

Moreover, the rising emphasis on sustainability and eco-friendliness is influencing the design and materials used in hydraulic seals. Manufacturers are focusing on developing seals that minimize leakages and reduce environmental impact, in line with stricter regulatory requirements. The market is witnessing a surge in demand for seals made from advanced materials, which not only provide superior sealing capabilities but also cater to the need for reduced maintenance and downtime in hydraulic systems. As the market continues to evolve, companies that prioritize innovation and sustainability will likely emerge as leaders in the hydraulic seals industry.

The Path Ahead for Hydraulic Seals in a Rapidly Evolving Market

This bar chart illustrates the market growth of hydraulic seals over the past few years and demonstrates the influence of key trends including industrial automation, demand in the automotive sector, and advancements in material technology.

Innovations in Materials and Technology for Enhanced Seal Performance

The hydraulic seals market is experiencing a transformative shift driven by innovative materials and technological advancements designed to enhance seal performance. According to a report by MarketsandMarkets, the global hydraulic seals market is projected to grow from USD 3.2 billion in 2023 to USD 4.2 billion by 2028, at a compound annual growth rate (CAGR) of 5.8%. This growth is fueled by the increasing demand for high-performance seals capable of withstanding extreme pressures and temperatures in various applications, including construction, aerospace, and agriculture.

Recent advancements in materials science have paved the way for the development of seals made from engineered polymers, such as polyurethanes and fluoroelastomers. These materials offer superior resistance to wear, chemical degradation, and extreme temperatures. A study from the Freudenberg Group highlighted that hydraulic seals manufactured with composite materials can extend equipment lifespans by up to 30%, thereby reducing maintenance costs and operational downtimes.

Furthermore, technology such as precision manufacturing and computer-aided design (CAD) is revolutionizing how hydraulic seals are produced. With the integration of advanced testing methods, manufacturers can now create seals that are not only more reliable but also tailored to specific operating conditions. As companies increasingly adopt smart manufacturing techniques, the ability to produce customized, high-performance hydraulic seals that meet stringent industry standards will become a crucial competitive advantage in this evolving market.

Regulatory Changes and Their Impact on Hydraulic Seal Standards

The rapidly evolving market for hydraulic seals is significantly influenced by recent regulatory changes, particularly those concerning per- and polyfluoroalkyl substances (PFAS). As both the U.S. and Europe impose stricter regulations on these substances, manufacturers are faced with the challenge of adapting their products to meet new compliance standards. The Hydraulic Institute has emphasized the importance of responding to these reporting requirements, urging companies to assess their use of PFAS and explore alternatives to minimize environmental impact.

In response to these regulatory pressures, there is a growing interest in next-generation biodegradable hydraulic fluids. These fluids not only address sustainability concerns but also tackle performance challenges that have historically limited their adoption in hydraulic systems. The ability to balance environmental sustainability with performance metrics is critical as companies strive to comply with emerging regulations while maintaining operational efficiency. Additionally, the European Sealing Association's advocacy for more selective regulations highlights the need for a nuanced approach, differentiating between harmful PFAS and safer alternatives. This approach will be essential in guiding the industry toward more responsible practices without compromising on quality or performance.

The Path Ahead for Hydraulic Seals in a Rapidly Evolving Market

This pie chart illustrates the distribution of various regulatory influences impacting hydraulic seal standards in 2023.

Market Challenges: Addressing Environmental and Durability Concerns

As the demand for hydraulic seals grows, the industry faces mounting challenges related to environmental sustainability and product durability. According to a recent report by MarketsandMarkets, the global hydraulic seals market is expected to reach $8.1 billion by 2026, driven by both construction and automotive sectors. However, increasing regulations surrounding environmental protection and sustainability are forcing manufacturers to innovate their materials and processes.

Concerns about the environmental impact of traditional seal materials have prompted a shift toward eco-friendly alternatives. For instance, biodegradable elastomers have gained traction as they reduce environmental footprints and address regulatory challenges. Furthermore, durability is a critical factor, given that hydraulic seals must operate under extreme pressures and various temperatures. A study by Research and Markets indicates that seals designed with advanced polymers can exhibit a lifespan improvement of up to 30% compared to conventional materials, significantly reducing failure rates and maintenance costs.

To navigate these challenges, the industry is prioritizing research and development, focusing on creating seals that not only adhere to environmental standards but also outperform their predecessors in durability. The path ahead will require a delicate balance between meeting environmental concerns and ensuring the reliability and longevity that end-users demand.

The Path Ahead for Hydraulic Seals in a Rapidly Evolving Market - Market Challenges: Addressing Environmental and Durability Concerns

| Challenge | Description | Impact on Market | Potential Solutions |

|---|---|---|---|

| Environmental Regulations | Increasing regulations around materials used in products requiring hydraulic seals. | May restrict the use of certain materials, increasing costs and complexity. | Development of eco-friendly materials and compliance strategies. |

| Durability Issues | Hydraulic seals must withstand harsh environments and extended usage. | Increased failure rates can lead to equipment downtime and higher replacement costs. | Innovative design and material research to enhance performance. |

| Cost Management | Rising costs in raw materials and manufacturing processes. | Pressure on margins and profitability for manufacturers. | Streamlining production and optimizing supply chains. |

| Technological Advancements | Adoption of smart technology, requiring compatible sealing solutions. | Need for seals that integrate with IoT and data-driven equipment. | Research and development in smart sealing technologies. |

Future Opportunities: Expanding Applications and Emerging Industries

The hydraulic seals market is poised for significant transformation as businesses seek to innovate and adapt to the demands of various emerging industries. With the increasing emphasis on sustainability and efficiency, hydraulic seals are finding new applications in sectors such as renewable energy, electric vehicles, and advanced manufacturing. These industries require reliable sealing solutions that can withstand high pressures and temperatures, making hydraulic seals more critical than ever.

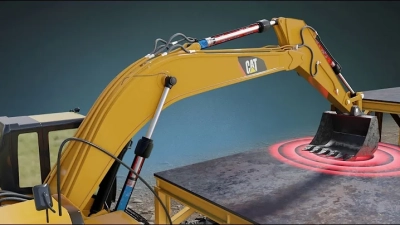

As technologies advance, the capabilities of hydraulic seals are also evolving. Developments in materials science are leading to seals that are not only more durable but also capable of functioning effectively in increasingly harsh environments. This creates an opportunity for manufacturers to tap into niche markets requiring specialized seals—such as those used in aerospace and medical devices—where precision and reliability are paramount. Furthermore, the rise of automation and smart manufacturing presents a unique opportunity for hydraulic seals to integrate with digital technologies, improving operational efficiency and predictive maintenance practices. As the market continues to grow, businesses that embrace these opportunities will be positioned for success in this rapidly evolving landscape.

Related Video

-

Excavators | The Marvels of Mechanical Engineering

View: 582266Channel: Sabin Mechanical Engineering -

Oil Seal Number | Oil Seal in Gearbox | Oil Seal Failures | Oil Seal

View: 247841Channel: Think and Achieve -

Dismantling a Hydraulic Cylinder #hydraulics #mechanic #manufacturing

View: 378574Channel: The Conrad Company