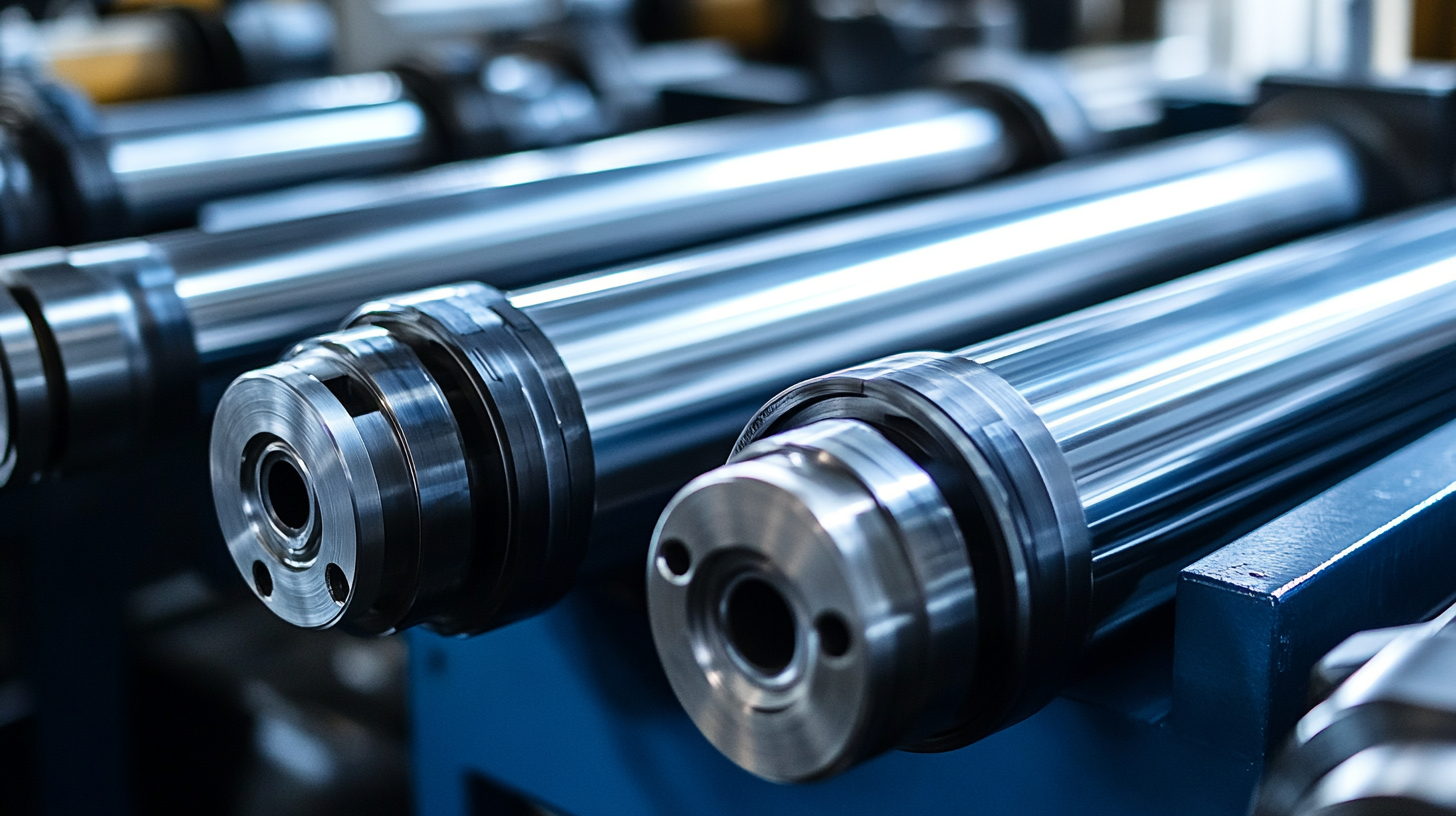

Understanding Global Import Standards: A Guide to Sourcing Custom Made Hydraulic Cylinders

Navigating the global marketplace these days can feel like quite the challenge, right? Sourcing products that meet all the specific requirements can be overwhelming, especially when we're talking about specialized industrial components like custom-made hydraulic cylinders. These components are super important across various industries, and getting a solid grasp on the import standards that apply to them is key for both manufacturers and suppliers. With the demand for tailored solutions increasing, it's really crucial to wade through the complexities of international regulations to stay compliant, ensure quality, and keep things running smoothly.

This guide is here to help clear up the import standards surrounding custom-made hydraulic cylinders and offer some valuable insights for businesses eager to refine their sourcing strategies. We’ll dive into everything from the certification requirements to the significance of maintaining quality assurance. By getting a handle on these essential points, you’ll be poised to make smarter decisions that not only boost your product lineup but also streamline your operations in this competitive global scene. So, let’s jump in and make sense of it all!

Understanding the Importance of Compliance with Global Import Standards for Hydraulic Cylinders

You know, understanding the ins and outs of compliance with global import standards is super important when you're looking to source custom-made hydraulic cylinders. With businesses getting into international trade—especially between countries like the US and China where things can get pretty complicated—it's not just about keeping the product quality up. It's also about dodging any potential legal issues that could come up. Companies really have to navigate this maze of regulations that differ from one country to another. So, having a solid grasp of those import standards can save a lot of headaches and avoid some pretty costly blunders down the line. Take recent changes in India, for example. They've tightened up their steel import regulations to help local industries fend off cheap foreign competition. This really shows how crucial it is to stick to the set standards. We’re seeing a shift globally toward stricter import controls, all aimed at protecting national interests. For folks manufacturing hydraulic cylinders, making sure production aligns with these compliance requirements isn't just about following the law—it's also a pretty smart business move that gives them a leg up on the competition. Meeting international quality benchmarks can really ease the way into different markets. And let’s not forget, as global logistics keep changing, companies have to stay on their toes about updates to import policies. Just look at the recent decision by the US Postal Service to change its stance on accepting packages from China. That’s a perfect example of how trade relations can shift rapidly and why keeping up with import standards is essential. By staying informed and being proactive, businesses can navigate these complexities, ensuring their hydraulic cylinders not only meet the market's demands but also shine in this challenging global landscape.

Key Specifications for Custom Made Hydraulic Cylinders Across Different Markets

You know, hydraulic cylinders are super important in all sorts of industries, from construction to manufacturing. When you're looking for custom-made hydraulic cylinders, it's really important to get a grip on the key specs that different markets need. I came across this report by MarketsandMarkets that says the global hydraulic cylinder market is on track to hit a whopping USD 17.1 billion by 2025! That really highlights how crucial it is to meet those standards if you want to stay ahead of the game.

Every market has its own requirements that vary depending on things like operational context and regulations. For instance, over in the European Union, those hydraulic cylinders have to meet the EN 10002 standard for tensile testing to make sure they’re durable and safe. Then you’ve got North America, where sticking to ISO 6020 and ISO 6022 standards for design and performance is the name of the game. Custom manufacturers also have to keep an eye on stuff like operating pressure, rod diameter, and stroke length because these details are usually influenced by the specific machinery and applications in those areas.

Now, let’s talk materials. A study from ResearchAndMarkets shows that carbon steel is still the go-to material since it’s strong and cost-effective. But for markets that need something tougher and more corrosion-resistant—like marine or offshore applications—stainless steel or special coatings are often required. Knowing these material specs can really set a supplier apart in a crowded market.

And don’t overlook quality assurance! Processes like leak testing and performance verification are super important when sourcing hydraulic cylinders. According to the Hydraulic Institute, doing proper testing and validation can actually cut warranty claims by up to 30%! That just goes to show how vital thorough quality checks are for meeting the varied needs of the market.

The Role of Quality Assurance in Sourcing Hydraulic Cylinders Internationally

You know, quality assurance is super important when it comes to sourcing hydraulic cylinders from around the world—especially if we’re talking about meeting those global import standards. As companies start to go global, making sure their products hit the right quality marks is more critical than ever. This is particularly the case for custom hydraulic cylinders; their specifications can really differ based on what they’re needed for. Having a solid quality assurance framework in place isn’t just about ticking boxes for international compliance; it actually helps build better relationships with suppliers, which in turn means you’re likely to get more reliable sources.

Recently, there’s been a real push from global organizations to highlight sustainable practices in procurement—something that totally links to quality assurance efforts in product sourcing. Take the United Nations Development Programme (UNDP) and the United Nations Office for Project Services (UNOPS), for example. They’ve kicked off projects that focus on cutting down carbon footprints and boosting small and medium-sized enterprises (SMEs) in the international arena. By weaving sustainability into quality assurance, companies can better tackle trade uncertainties while making sure their hydraulic cylinders are not only compliant but also eco-friendly.

And let’s not forget, this commitment to quality assurance is also really noticeable in healthcare. Just look at how the World Health Organization (WHO) recently added new diagnostics for monkeypox to its emergency use list. This just goes to show that strict quality standards are key not just in industries but across the board. For businesses that are sourcing hydraulic cylinders, it’s a big reminder that having thorough quality assurance processes is vital for meeting those regulatory requirements and ensuring the health and safety of users everywhere.

Analyzing Regional Differences in Import Regulations for Hydraulic Components

When it comes to sourcing custom-made hydraulic cylinders, one of the most important things to keep in mind is the regional differences in import regulations. Seriously, each country has its own set of standards, and this can really influence how hydraulic components are designed, built, and certified. For instance, in the U.S., the American Society of Mechanical Engineers (ASME) has some pretty strict guidelines, while over in the European Union, they follow the PED (Pressure Equipment Directive). This is all about safety and making sure every member country is on the same page.

A report from the International Trade Centre in 2022 mentioned that the global hydraulic cylinder market pulled in around $2.5 billion in revenue. And guess what? It’s expected to grow by about 7.5% every year! But along with that growth, there’s also more regulatory scrutiny coming into play. Take Asia, for example; countries like China have been stepping up their standards to keep a closer eye on quality control and environmental compliance. This is especially true for hydraulic systems used in construction and agriculture. So, if you’re manufacturing or supplying, grasping these differences is super important if you want to navigate the tricky waters of international trade without getting lost.

Another thing to think about is that differences in testing and certification processes can really slow things down and rack up extra costs. Like, if you’re a hydraulic manufacturer trying to export to Australia, you’ll need to follow the Australian Standards (AS 4020), which require testing for materials that come into contact with drinking water. This kind of requirement is often not as strict in many Asian countries. So yeah, knowing about these regional standards isn’t just helpful; it’s a must for avoiding costly mistakes and boosting your competitiveness on the global stage.

Case Studies: Successful Sourcing Strategies for Custom Hydraulic Cylinders

You know, in recent years, the way we source custom hydraulic cylinders has really changed a lot. It's kind of wild how many things are influencing it—like global import standards and companies making strategic acquisitions. A great example is when Dellner Bubenzer from Sweden acquired Hydratech Industries. This move shows just how companies are changing things up to stay competitive in the hydraulic systems game. Thanks to this merger, Dellner Bubenzer isn’t just adding more products to their lineup; they’re also building a global network that can better cater to a bunch of different industries, like wind energy and marine applications.

When it comes to sourcing strategies for these custom cylinders, it’s not just about the basics anymore. Companies really need to get a grip on both international standards and what the local market actually needs. For example, they have to make sure they comply with safety and performance regulations, but they also have to keep an eye on costs for materials and components. It’s all about balancing those factors. That’s where advanced tech like big data and cloud manufacturing come into play—they really help manufacturers make smarter choices and streamline their operations.

Plus, if we look at case studies from industry leaders, it’s clear that being adaptable is key when it comes to sourcing strategies. Companies can learn a lot from recent ups and downs in the market. For instance, maritime-related stocks took a hit, but businesses can use data analytics to help manage risks tied to sourcing. Take Liebherr, for example; they’re showcasing cool innovations like CFRP composite hydraulic cylinders at international trade shows. It just goes to show that a proactive approach is crucial to staying relevant in this constantly changing landscape. By adopting these smarter strategies, firms can really tackle the complexities of global sourcing while ensuring that the custom hydraulic cylinders they produce are top-notch.