Unlocking Efficiency: Essential Insights for Sourcing High-Performance Hydraulic Rams Globally

The global hydraulic rams market is witnessing significant transformation, driven by advancements in engineering technologies and increasing demand across various industries. According to a report by MarketsandMarkets, the hydraulic equipment market is projected to grow from $39.35 billion in 2020 to $54.25 billion by 2025, at a CAGR of 6.8%. Hydraulic rams, as critical components within this ecosystem, play an essential role in applications ranging from construction and agriculture to manufacturing and automotive industries. Their efficiency, durability, and versatility make them indispensable in facilitating heavy lifting and precise movements.

As organizations seek to enhance operational efficiency and reduce downtime, sourcing high-performance hydraulic rams has become a top priority. High-quality hydraulic rams not only contribute to improved productivity but also ensure safety and reliability in demanding environments. The importance of selecting the right provider cannot be overstated; comprehensive evaluations that consider production capabilities, material quality, and supply chain efficiency can spell the difference between operational success and costly setbacks. This blog aims to provide essential insights into effectively sourcing hydraulic rams globally, ensuring that businesses remain competitive in a rapidly evolving marketplace.

Identifying Key Performance Indicators for Hydraulic Rams

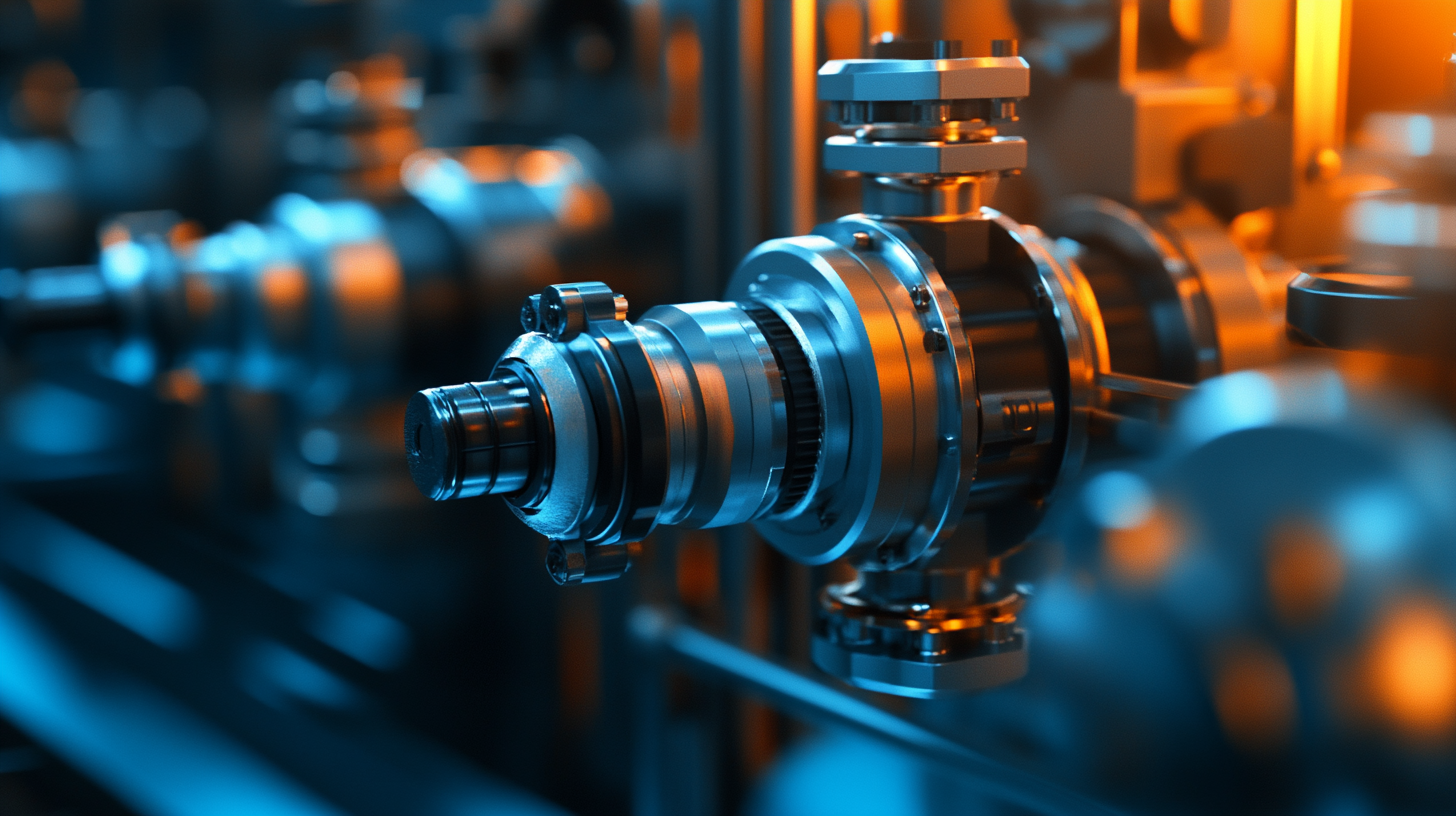

In today’s dynamic industrial landscape, the efficiency of hydraulic rams is paramount for optimizing operations across various sectors. To ensure high performance, it's essential to identify and measure key performance indicators (KPIs) that can guide sourcing decisions. These KPIs typically include operating pressure, stroke length, response time, and load capabilities. By focusing on these metrics, businesses can effectively evaluate the performance potential of hydraulic rams before making a procurement decision. Transitioning from hydraulic to electric actuators is a significant shift that many industries are considering. Understanding the necessary steps for this conversion not only highlights the evolving landscape but also poses a challenge for the sourcing of hydraulic rams. Accurately assessing the loads and forces required by the application is crucial, as it informs both the selection process and the long-term operational reliability of the rams. This level of precision ensures that sourced hydraulic solutions meet the demands of modern engineering requirements while maintaining efficiency. Further, as companies navigate this transition, they must also evaluate the operational implications of hydraulic versus electric systems. Each offers distinct advantages that can impact performance metrics. By meticulously analyzing both systems through the lens of established KPIs, stakeholders can make informed decisions that align with their operational goals and sustainability initiatives.

Navigating Global Supply Chains: Choosing the Right Suppliers

In today's dynamic landscape, effectively navigating global supply chains is critical for companies sourcing high-performance hydraulic rams. As the geopolitical climate evolves, businesses must be acutely aware of emerging risks, particularly with the recent reelection of political figures poised to enact significant trade policy changes. According to industry reports, supply chain disruptions have consistently ranked among the top ten risks for organizations, highlighting the importance of robust supplier evaluation and relationship management.

To mitigate these risks, companies are turning to strategies like "glocalization," which balances global sourcing with local supply chain efficiencies. A report from a leading market analysis firm indicates that organizations employing this approach have seen up to a 30% improvement in supply chain resilience. By collaborating with local suppliers, businesses can enhance responsiveness to market changes and minimize delays caused by international shipping uncertainties.

Moreover, as companies increasingly integrate Environmental, Social, and Governance (ESG) criteria into their vendor assessments, the focus on due diligence is more pronounced. Research indicates that companies that prioritize ESG compliance in their supply chains not only reduce risks but also drive long-term value, demonstrating a commitment to sustainability. This strategic alignment not only satisfies regulatory requirements but also enhances brand reputation in a market that increasingly favors socially responsible practices.

In summary, for businesses sourcing hydraulic rams, navigating the complexities of global supply chains requires a proactive approach towards supplier selection, risk management, and adherence to evolving market trends. Leveraging data-driven insights and fostering strong supplier relationships will be key to unlocking efficiency in an unpredictable environment.

Cost vs. Quality: Finding the Perfect Balance in Hydraulic Rams

When sourcing hydraulic rams, striking the right balance between cost and quality is crucial for ensuring optimal performance in various applications. Recent advancements highlight the transformative role hydraulic cylinders play in infrastructure, exemplified by their use in the US Bank Stadium, which leverages multiple hydraulic rams to operate massive pivoting glass doors. This innovative deployment emphasizes the importance of selecting high-performance hydraulic rams that not only meet operational demands but also enhance the overall efficiency of systems.

Investing in high-quality hydraulic rams can significantly reduce maintenance costs and downtime. While the initial financial outlay may be higher, the long-term benefits of durability and reliability can outweigh the savings from opting for cheaper alternatives. Effective sourcing strategies should focus on evaluating supplier offerings based on performance specifications, material quality, and longevity, ensuring that the chosen hydraulic rams can withstand the rigors of their intended applications.

In a global marketplace, it becomes essential to assess both local and international suppliers. By carefully considering factors such as production standards, technology innovations, and customer feedback, businesses can find suppliers that provide high-performance rams that align with their project requirements. Ultimately, the quest for the perfect balance between cost and quality is vital for leveraging hydraulic technology effectively and achieving operational excellence.

Innovations in Hydraulic Technologies and Their Impact on Sourcing

In the realm of hydraulic technologies, recent innovations are setting a new standard for sourcing high-performance hydraulic rams. Industry leaders are increasingly integrating electric components to enhance the efficiency and performance of hydraulic systems. The combination of electric and hydraulic technologies not only addresses the urgent demand for cleaner solutions but also optimizes operational efficiency in demanding applications. A report from the Hydraulics Industry Association indicates that the market for electric hydraulic systems is projected to grow by 23% annually through 2026, highlighting the shift towards smarter and more sustainable machines.

Furthermore, the recent advancements in wearable robotics for mobility assistance shed light on how hydraulic innovations can transcend traditional applications. With companies receiving significant funding to develop these next-generation technologies, the implications for the hydraulic sector are profound. For instance, integrating hydraulic systems into wearable devices can enhance fluid dynamics, providing more responsive and adaptive support for users. This integration reflects a broader trend of merging hydraulic capabilities with advanced data analytics to improve user experience and operational outcomes.

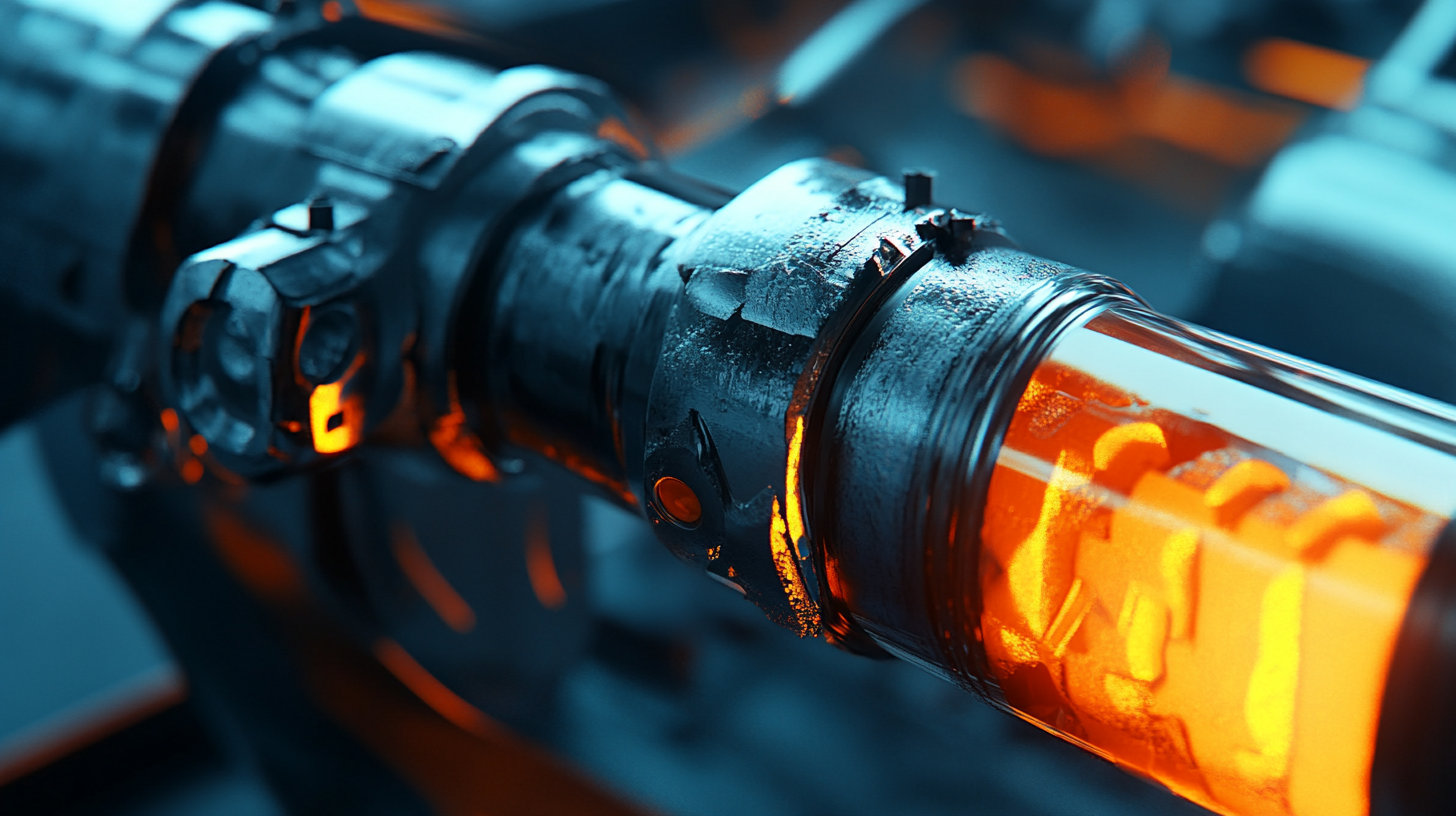

Additionally, the launch of innovative hydraulic coupling solutions points to a pivotal moment in the market. New designs are not only more compact but also promise improved performance and reliability, which could be critical for industries reliant on excavators and other heavy machinery. Such breakthroughs in hydraulic coupling technology are essential as demand for versatility in applications increases globally. As sourcing practices evolve under the influence of these technological advancements, staying informed about these innovations will be key for manufacturers looking to maintain a competitive edge.

Ensuring Compliance and Standards in Global Hydraulic Ram Procurement

In the ever-evolving landscape of global procurement, ensuring compliance and standards in hydraulic ram sourcing has become paramount. As industries increasingly prioritize responsible purchasing practices, it is essential to align procurement strategies with ethical standards and regulatory requirements. Recent findings highlight that companies with robust governance frameworks are better positioned to foster integrity and responsibility throughout their supply chains. This cultural commitment not only enhances brand reputation but also mitigates risks associated with non-compliance.

The electronics industry serves as a pertinent example, where public procurement initiatives have emerged as powerful tools for promoting human rights and ethical sourcing practices. A comprehensive study on collaboration and due diligence in this sector reveals that organizations prioritizing ethical sourcing witness a 20% reduction in supply chain disruptions and a significant improvement in supplier partnership quality. As such, adopting similar approaches in hydraulic ram procurement can lead to enhanced operational sustainability and compliance with global standards.

Moreover, emerging market trends indicate a growing emphasis on environmental compliance, particularly in the context of lead-free solder requirements. The increasing pressure on manufacturers to abide by these regulations underscores the importance of sourcing from suppliers who meet international environmental standards. By doing so, organizations not only comply with current regulations but also position themselves favorably for future market dynamics.

Ultimately, in a global economy where compliance and standards are critical, hydraulic ram procurement must move beyond mere transactional relationships. Organizations that invest in building strategic partnerships and implementing risk-based controls will undoubtedly outperform their competitors, securing both operational efficiency and ethical integrity in their sourcing endeavors.