Essential Guide to Understanding Hydraulic Cylinder Parts: Key Components and Their Impact on Performance

In the realm of industrial machinery, hydraulic cylinders are pivotal components that drive performance and efficiency across various applications. According to a recent market research report by Research and Markets, the global hydraulic cylinder market is projected to grow from $12 billion in 2021 to over $18 billion by 2027, underscoring the increasing reliance on hydraulic technologies in sectors such as construction, agriculture, and manufacturing. Understanding the intricacies of hydraulic cylinder parts is crucial, as these key components—including the piston, seals, and rods—significantly influence the system's operational capability and longevity. As industries continue to seek optimized performance and reduced downtime, mastering the composition and functionality of hydraulic cylinder parts becomes an essential strategy for enhancing equipment reliability and efficiency.

Understanding the Functionality of Hydraulic Cylinders: A Comprehensive Overview

Hydraulic cylinders are crucial components in many hydraulic systems, enabling the conversion of hydraulic energy into mechanical force. Understanding their functionality is essential for optimizing performance in a variety of applications, from heavy machinery to automotive systems.

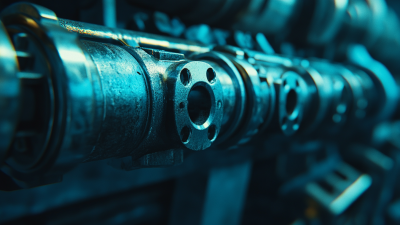

A hydraulic cylinder typically consists of a cylinder barrel, piston, and rod. The movement of the piston within the cylinder converts the pressurized hydraulic fluid into linear motion, which is harnessed to perform work, such as lifting, pushing, or pulling heavy loads.

Hydraulic cylinders are crucial components in many hydraulic systems, enabling the conversion of hydraulic energy into mechanical force. Understanding their functionality is essential for optimizing performance in a variety of applications, from heavy machinery to automotive systems.

A hydraulic cylinder typically consists of a cylinder barrel, piston, and rod. The movement of the piston within the cylinder converts the pressurized hydraulic fluid into linear motion, which is harnessed to perform work, such as lifting, pushing, or pulling heavy loads.

The performance of a hydraulic cylinder heavily depends on the interplay of its key components. The design and material of the cylinder barrel affect its ability to withstand high pressure while minimizing wear and tear. The piston seal's efficiency plays a pivotal role in preventing leaks and ensuring that the hydraulic fluid remains pressurized. Additionally, the rod must possess sufficient strength and accuracy to maintain alignment, which is critical for smooth operation.

By comprehending these elements and their impact on performance, users can better maintain and enhance the efficiency of hydraulic systems, leading to improved reliability and operational longevity.

Key Components of Hydraulic Cylinders: A Breakdown of Each Part's Role

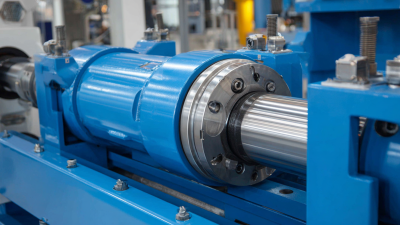

Hydraulic cylinders are critical components in various industrial applications, and understanding their key parts can significantly enhance performance. At the heart of a hydraulic cylinder is the barrel, which houses the piston and fluid. The design and material of the barrel can influence both the strength and durability of the cylinder. Modern cylinders often utilize high-quality steel, which can withstand greater pressures, leading to improved efficiency. According to a 2022 report by the International Fluid Power Society, maintenance of these key components can lead to up to a 30% increase in operational lifespan, highlighting their importance.

The piston is another vital part, converting hydraulic energy into mechanical work. The interaction between the piston and the fluid dynamics dictated by the cylinder’s design determines the overall efficiency of the system. Incorporating advanced sealing technologies can enhance performance, minimizing leakage and reducing energy loss. As noted in a recent study by the American Society of Mechanical Engineers, effective sealing can improve a hydraulic system's efficiency by as much as 15%.

**Tips:** Regularly inspect your hydraulic cylinders for signs of wear, particularly in seals and connections. Maintaining optimal fluid levels and using high-grade hydraulic fluids can also play a crucial role in prolonging the life of these components. Additionally, investing in quality parts may offset initial costs through enhanced performance and reduced downtime.

Hydraulic Cylinder Components and Their Impact on Performance

How Cylinder Design Influences Performance: Analyzing Shape and Size

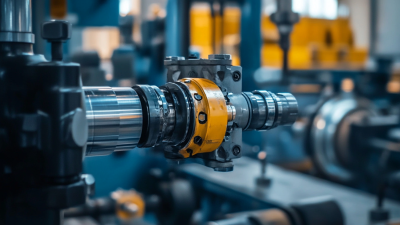

The design of hydraulic cylinders is crucial in determining their overall performance, with both shape and size playing significant roles. Research indicates that the cylinder's diameter directly influences the force output. For example, an increase in the bore diameter by 25% can result in a force increase of nearly 56%, given the same pressure conditions. This relationship underscores the importance of selecting the appropriate diameter to meet specific operational requirements.

Additionally, the length of the cylinder affects not only the stroke length but also the overall stability during operation. A longer cylinder provides a greater stroke but may compromise stability due to increased bending moments. According to a study by the International Journal of Fluid Power, optimizing cylinder length for application-specific requirements can improve efficiency by up to 30%. Moreover, the shape of the end caps and the design of the rod can also influence flow dynamics, potentially impacting hydraulic efficiency and response times. Understanding these design factors is essential for engineers looking to enhance the performance of hydraulic systems across various industries.

Essential Guide to Understanding Hydraulic Cylinder Parts: Key Components and Their Impact on Performance

| Component | Material | Size (mm) | Impact on Performance |

|---|---|---|---|

| Cylinder Tube | Steel | 100 - 200 | Determines pressure holding capacity and durability. |

| Piston | Aluminum | 50 - 150 | Affects movement speed and force output. |

| Seals | Rubber | Varies | Prevents fluid leakage and maintains pressure. |

| Rod | Chrome-Plated Steel | 20 - 50 | Influences cycle life and resistance to wear. |

| End Caps | Steel | Varies | Holds components together and withstands internal pressure. |

Maintaining Hydraulic Cylinders: Best Practices for Optimal Performance

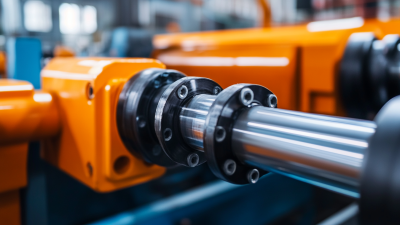

Maintaining hydraulic cylinders is crucial for ensuring their longevity and performance. According to a report by the International Fluid Power Society, proper maintenance can extend the lifespan of hydraulic components by up to 30%. Regular inspections to detect leaks, wear, and contamination are essential practices. A study from the Hydraulic Institute revealed that nearly 70% of hydraulic system failures can be attributed to inadequate maintenance, emphasizing the importance of a structured maintenance routine.

One of the best practices in hydraulic cylinder maintenance is to regularly check and replace fluid. Contaminated hydraulic fluid can lead to increased wear on the cylinder components and inefficiency in operation. The Fluid Power Journal recommends monitoring fluid cleanliness levels, aiming to keep them below NAS 1638 Class 7 for optimal performance. Additionally, ensuring that seals and rod bearings are properly lubricated can significantly reduce friction, subsequently enhancing efficiency. Utilizing predictive maintenance technology, such as vibration analysis and temperature monitoring, can help in anticipating issues before they escalate, thereby further improving the reliability and effectiveness of hydraulic cylinders.

Troubleshooting Common Hydraulic Cylinder Issues: When to Seek Professional Help

Hydraulic cylinders are vital components in various industrial applications, and understanding common issues they face is essential for maintaining optimal performance. According to a report by the International Fluid Power Society, approximately 30% of hydraulic system failures can be attributed to issues within the cylinders themselves. Common problems include leaking seals, cylinder rod wear, and hydraulic fluid contamination. These issues often lead to decreased efficiency and increased downtime, which can significantly impact overall productivity.

When encountering persistent hydraulic cylinder problems, it is crucial to know when to seek professional help. Experts suggest that if a leak recurs even after attempting repairs, it may indicate deeper issues such as misalignment or internal damage. Additionally, regular monitoring of hydraulic fluid quality is essential; the condition of the fluid can dramatically influence the lifespan of the hydraulic system. A study from the National Fluid Power Association found that maintaining clean fluid could extend hydraulic component life by up to 50%. Engaging with professionals can save both time and costs in the long run, ensuring that hydraulic cylinders function effectively and reliably in demanding environments.

Related Posts

-

Overcoming Common Challenges with High Pressure Hydraulic Cylinders: Solutions for Success

-

China Manufacturing Thrives with Best Hydraulic Cylinder Parts Amidst US China Tariff Challenges

-

Top Strategies for Optimizing Your Best Hydraulic Cylinder System Performance

-

Innovative Strategies for Effective Hydraulic Cylinder Maintenance and Repair Solutions

-

Essential Factors to Consider When Sourcing Pneumatic Hydraulic Cylinders for Your Business

-

How to Identify Top 7 Manufacturers of Hydraulic Cylinders for Global Buyers