Ultimate Guide to Hydraulic Cylinder Service Tips for Optimal Performance

Hydraulic cylinders play a crucial role in various industrial applications, providing the power necessary for lifting, pushing, and moving heavy loads. According to a report by Markets and Markets, the global hydraulic cylinder market is projected to reach $20.5 billion by 2026, with a compound annual growth rate (CAGR) of 5.1% from 2021 to 2026. This growth underscores the importance of maintaining optimal performance through effective Hydraulic Cylinder Service, which can significantly enhance the longevity and efficiency of hydraulic systems.

Regular maintenance and timely servicing are vital in preventing costly breakdowns and unscheduled downtimes. A study by the International Hydraulic Engineering Association indicates that improper maintenance can reduce the lifespan of hydraulic cylinders by up to 40%. Given the significant investments in hydraulic equipment, companies must adopt best practices in Hydraulic Cylinder Service to maximize their returns. This guide aims to provide insightful tips and techniques that will help operators and maintenance teams keep hydraulic cylinders in peak condition, ensuring operational reliability and safety in their applications.

Understanding Hydraulic Cylinder Basics for Effective Service

Hydraulic cylinders are crucial components in various industrial applications, providing linear motion and force. Understanding their basic operation is essential for effective maintenance and service. At their core, hydraulic cylinders operate on Pascal's principle, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. This fundamental principle allows cylinders to convert hydraulic energy into mechanical power, enabling machinery such as excavators and lifting systems to perform efficiently.

According to a report by the International Organization for Standards (ISO), about 85% of hydraulic system failures are due to improper maintenance rather than defective components. Regular service practices such as fluid level checks, contamination analysis, and seal inspections can significantly extend the life of a hydraulic cylinder. Research from the National Fluid Power Association (NFPA) indicates that maintaining optimal fluid cleanliness can enhance performance by 30%. Furthermore, adopting a preventive maintenance schedule can lead to a 20% reduction in unplanned downtime, emphasizing the importance of understanding the operational basics of hydraulic cylinders for effective service.

Key Components of Hydraulic Cylinders and Their Functions

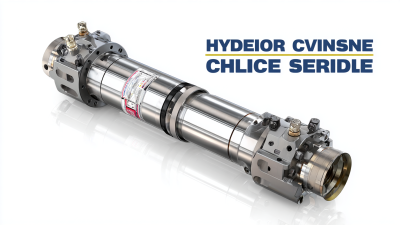

Hydraulic cylinders are essential components in various machinery and equipment, performing critical tasks by converting hydraulic energy into mechanical force. Understanding the key components of hydraulic cylinders—such as the cylinder barrel, piston, seals, and hydraulic fluid—is fundamental for optimizing their performance. The cylinder barrel houses the piston, allowing it to move seamlessly while maintaining structural integrity. The piston is designed to create pressure, facilitating powerful movements essential in applications ranging from construction to manufacturing. According to industry reports, properly maintained hydraulic cylinders can operate efficiently for thousands of hours, significantly reducing downtime and maintenance costs.

Tips for enhancing hydraulic cylinder life include regular inspection of seals and hydraulic fluid levels. Worn out seals can lead to fluid leakage, compromising performance and efficiency. It's crucial to use high-quality hydraulic fluid that meets the specifications required by your equipment, as this can increase the lifespan of both the cylinder and its components. Another important aspect is ensuring that the cylinder is free from contaminants; implementing a strict cleanliness protocol during maintenance can prevent damage and extend operational life.

For optimal performance, keep an eye on the operational pressures indicated in manufacturer guidelines, as exceeding these limits can lead to cylinder failure. Regularly monitor the hydraulic system for any unusual noises or movements, which can signal underlying issues. By adhering to these service tips and understanding the critical elements of hydraulic cylinders, operators can achieve enhanced efficiency and longevity in their operational environments.

Step-by-Step Guide to Effective Hydraulic Cylinder Maintenance

Effective hydraulic cylinder maintenance is crucial for ensuring longevity and optimal performance of your machinery. To begin, regularly inspect the cylinder for any signs of wear or damage. This includes checking for leaks, which can indicate seal failure, as well as examining the rod and barrel for scratches or corrosion. Implementing a routine visual inspection can help detect issues early, preventing costly repairs and downtime.

Next, proper lubrication plays a vital role in maintaining hydraulic cylinders. Utilizing the right type of hydraulic fluid is essential, as it not only reduces friction but also protects against rust and corrosion. Ensure that fluid levels are adequate and that the fluid is clean to prevent contaminants from entering the system. When changing the hydraulic fluid, make sure to follow the manufacturer's guidelines regarding intervals and disposal methods to maintain environmental compliance.

Finally, regular operational testing can aid in identifying any performance issues. Monitor for unusual noises or changes in response time, which may indicate mechanical issues within the cylinder. Keeping a detailed maintenance log of inspections, fluid changes, and any repairs made can help track performance trends and anticipate future maintenance needs, thus maximizing the efficiency and lifespan of hydraulic cylinders. By adhering to these step-by-step maintenance guidelines, you can ensure reliable operation and prevent unexpected failures.

Ultimate Guide to Hydraulic Cylinder Service Tips for Optimal Performance

| Maintenance Task | Frequency | Description | Tools Required |

|---|---|---|---|

| Visual Inspection | Daily | Check for leaks, damage, or wear. | None |

| Fluid Level Check | Weekly | Ensure hydraulic fluid is at the correct level. | Dipstick or sight glass |

| Seal Inspection | Monthly | Examine seals for wear or damage. | None |

| Fluid Quality Check | Quarterly | Ensure fluid is clean and free of contaminants. | Hydraulic fluid tester |

| Filter Replacement | Annually | Replace hydraulic filters to maintain efficiency. | New filter, wrench |

| Full System Service | Bi-Annually | Complete service including fluid change and component checks. | Various tools, new fluid |

Common Issues in Hydraulic Cylinders and How to Troubleshoot Them

When it comes to hydraulic cylinders, understanding common issues and how to troubleshoot them is essential for maintaining optimal performance. One frequent problem is leakage, which can significantly impact the efficiency of your machinery. To address this issue, start by inspecting the seals and gaskets for any signs of wear or damage. Regularly replacing these components can prevent leakage and ensure the cylinder operates smoothly. Additionally, it's important to check for contamination in the hydraulic fluid, as dirty fluid can cause blockages and premature wear.

Another common issue is corrosion, which can weaken the integrity of the cylinder and affect its functionality. To combat corrosion, ensure that your cylinders are properly maintained and cleaned regularly. Using protective coatings can also safeguard the metal surfaces from environmental factors. If you encounter corrosion, it may be necessary to refurbish the affected components or replace them entirely to restore the cylinder's performance.

Tips for effective hydraulic cylinder maintenance include always following manufacturer guidelines for service intervals and using the right hydraulic fluid. Regularly checking pressure levels can help identify potential issues before they escalate. Additionally, training personnel on proper handling techniques minimizes the risk of damage, ensuring that your hydraulic systems continue to operate efficiently.

Best Practices for Optimizing Hydraulic Cylinder Performance

Hydraulic cylinders are pivotal in various industries, from construction to manufacturing, serving as the backbone of many heavy machinery operations. To optimize their performance, implementing best practices is essential. According to a report by the International Fluid Power Society, proper maintenance can extend the life of hydraulic systems by up to 50%, significantly reducing downtime and replacement costs.

One key tip for enhancing hydraulic cylinder performance is regular inspection and maintenance. Checking fluid levels, seals, and connections helps identify potential issues before they escalate. It is advisable to replace filters regularly; clean fluid is crucial for the longevity and efficiency of hydraulic components. As noted by the Fluid Power Journal, neglecting these simple checks can lead to a 70% increase in system failures.

Another best practice involves monitoring operating temperatures. Research from the National Fluid Power Association indicates that hydraulic systems should ideally operate between 120°F and 180°F. Operating above this range can accelerate wear and tear on components. Installing temperature gauges or alerts can help maintain optimal operating conditions, ensuring the hydraulic cylinders perform effectively over time. Implementing these practices not only maximizes performance but also contributes to a safer working environment.

Related Posts

-

Understanding Industry Standards: How to Choose the Best Hydraulic Cylinder Service for Your Needs

-

The Complete Blueprint to Mastering Hydraulic Cylinder Service

-

How to Extend the Lifespan of Your Hydraulic Cylinder Service

-

Hydraulic Cylinder Rebuilders Shine at Canton Fair 2025 with Record International Attendance

-

Navigating the 2025 Tech Landscape: A Comprehensive Checklist for Optimal Hydraulic Cylinder Service

-

Exploring Diverse Alternatives for Hydraulic Cylinder Replacement Parts