Exploring the Varieties and Applications of Hydraulic Pistons in Modern Industries

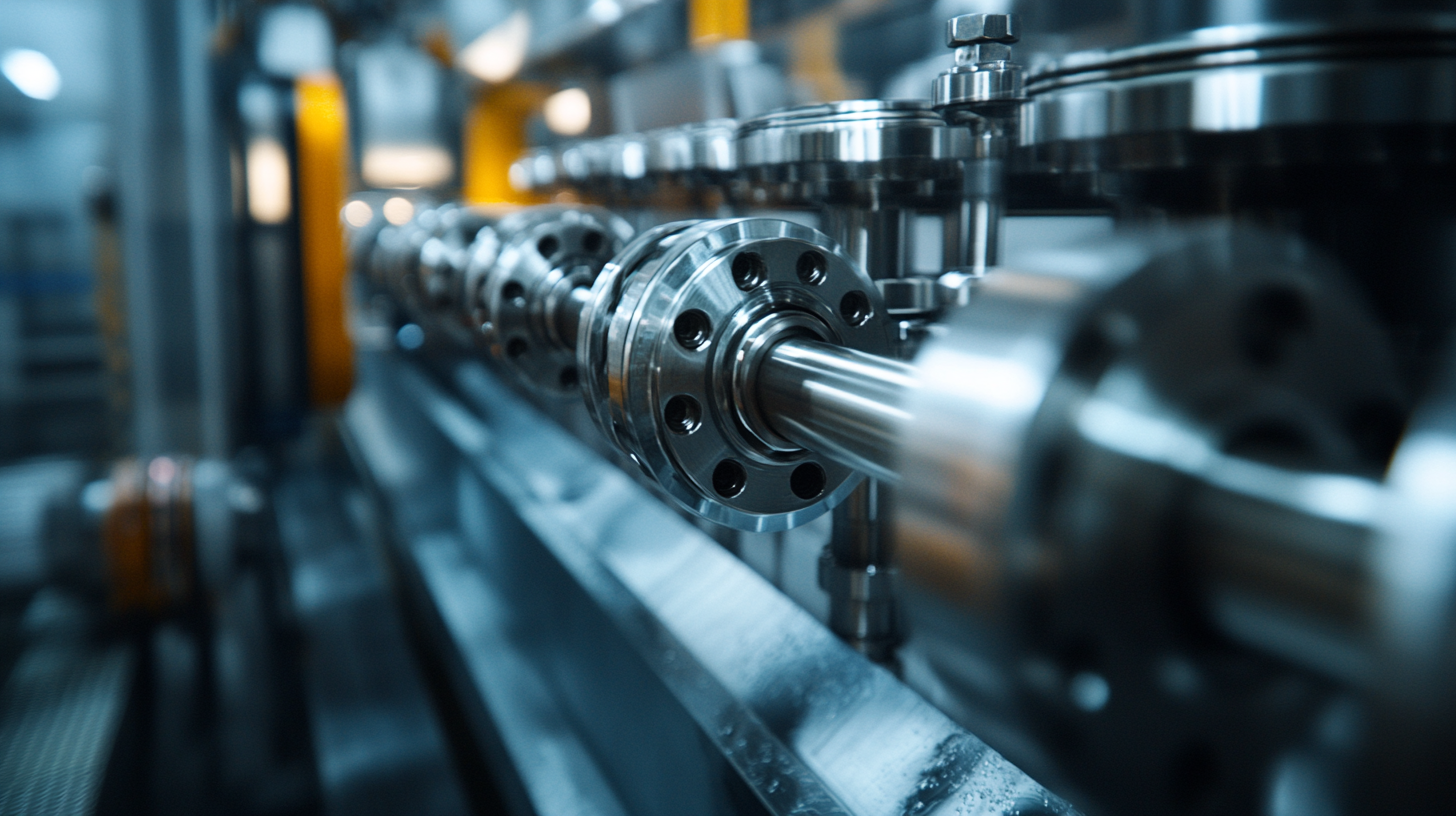

In the realm of modern engineering and industrial applications, the hydraulic piston stands out as a pivotal component that drives efficiency and power. These ingenious devices convert hydraulic energy into mechanical energy, providing the necessary force to operate machinery across various sectors. From construction sites to manufacturing plants, hydraulic pistons play a crucial role in enabling equipment to perform demanding tasks with precision and reliability. Their versatility and effectiveness make them indispensable in a world increasingly reliant on automation and heavy-duty mechanisms.

As we delve deeper into the diverse applications and types of hydraulic pistons, it becomes evident that their impact extends beyond mere mechanical function. They serve as the backbone of many systems, enhancing performance in industries such as automotive, aerospace, and renewable energy. Understanding the different varieties of hydraulic pistons and their specific uses not only highlights their significance but also showcases ongoing innovations that continue to shape industrial practices. Join us as we explore the extensive world of hydraulic pistons and uncover how these remarkable devices are transforming modern industries.

Understanding the Basics: What are Hydraulic Pistons and How They Work

Hydraulic pistons play a crucial role in various modern industries, functioning as essential components in hydraulic systems. These components utilize the principles of fluid mechanics to generate force and motion. By applying pressure to a fluid, hydraulic pistons can lift heavy loads, drive machinery, and provide precise control in applications ranging from construction equipment to automotive manufacturing. According to industry reports, the hydraulic components market is projected to reach approximately $55 billion by 2026, driven by the increasing demand for automation and electrification across sectors. In understanding how hydraulic pistons operate, it's vital to recognize their core elements: the cylinder, piston, and hydraulic fluid. As the hydraulic fluid is pressurized, it acts upon the surface area of the piston, resulting in linear motion. This efficiency is further enhanced by advancements in technology, such as electromechanical cylinders, which provide significant performance benefits and are currently reshaping applications in industrial automation. Recent innovations also showcase how hydraulic systems are pushing boundaries in subsea operations, fulfilling the growing need for resources to meet global demands. The integration of hydraulic pistons extends to a variety of applications beyond traditional heavy machinery. For example, sports venues are employing hydraulic cylinders in sophisticated entrance designs, allowing for the seamless operation of large pivoting doors. Such developments illustrate the adaptability of hydraulic technology, catering to both functional performance and aesthetic requirements. As industries continue to innovate and explore new horizons, the versatility of hydraulic pistons remains a cornerstone of modern engineering solutions.

The Different Types of Hydraulic Pistons and Their Unique Features

Hydraulic pistons play a crucial role in various modern industries, providing the power needed for diverse applications. There are several distinct types of hydraulic pistons, each engineered for specific functions and performance characteristics. Axial pistons, for example, are designed to transmit high pressure efficiently and are often used in hydraulic motors and pumps. Their cylindrical shape and the arrangement of their pistons in parallel allow them to deliver smooth, consistent power, making them ideal for heavy machinery and mobile equipment.

Another type is the radial piston, which operates through radial movement and is typically more compact than its axial counterpart. This design often results in high torque and is utilized in applications such as construction equipment, where space is at a premium but power is critical. Additionally, variable displacement pistons and fixed displacement pistons serve distinct needs in hydraulic systems. Variable displacement pistons can adjust the flow and pressure as required, providing versatility in dynamic applications, while fixed displacement pistons deliver a set amount of fluid per stroke, making them suitable for more straightforward tasks.

Understanding the unique features of these hydraulic pistons allows industries to choose the right components for their specific needs, ultimately enhancing efficiency and performance. As the hydraulic cylinder market continues to grow, projected to reach USD 18.3 billion by 2027, the importance of selecting the appropriate type of hydraulic piston will become even more significant in optimizing industrial processes and innovations.

Key Industries Utilizing Hydraulic Pistons for Enhanced Efficiency

Hydraulic pistons are integral components across various modern industries, significantly enhancing efficiency and performance. The global hydraulic cylinder market was estimated to be worth USD 14.3 billion in 2021 and is projected to reach USD 18.3 billion by 2027. This growth reflects the increasing adoption of hydraulic systems in sectors such as construction, manufacturing, and automotive, where precision and power are essential.

One of the prominent applications of hydraulic pistons is in multi-stage telescopic hydraulic cylinders, widely utilized in cranes, trucks, and factories. These cylinders are designed to accommodate large working distances, providing the lifting power necessary for heavy loads in construction and logistics. Furthermore, the design challenges associated with structural safety and sealing analysis in these systems underscore the importance of innovation in hydraulic technologies.

Additionally, the plastic injection molding machines market is experiencing substantial growth, with a valuation of USD 7.63 billion in 2023 and a projected compound annual growth rate of 5% from 2024 to 2032. Hydraulic pistons play a crucial role in these machines, enabling precision in shaping thermoplastics and ensuring high productivity in manufacturing processes.

Complementing these advancements is the hydraulic power unit market, expected to grow at a CAGR of 5.5%. This demand correlates with various industries seeking optimized operating pressures and efficient pump types to streamline operations. As these sectors continue to evolve, the role of hydraulic pistons in fostering efficiency and innovation remains paramount.

Innovative Technologies in Hydraulic Piston Design and Manufacturing

Innovative technologies in hydraulic piston design and manufacturing have transformed the landscape of modern industries, pushing the boundaries of efficiency and performance. Advanced materials such as composite alloys and high-strength steels have revolutionized the crafting of hydraulic pistons, allowing for lighter designs that do not compromise strength. Additionally, the integration of computer-aided design (CAD) software enhances the precision of piston components, ensuring exact specifications are met during the manufacturing process. This level of accuracy not only improves the operational reliability of hydraulic systems but also extends their lifespan.

Furthermore, the advent of 3D printing technology is reshaping the future of hydraulic piston production. By enabling the creation of complex geometries that would be difficult or impossible to achieve through traditional methods, 3D printing allows for greater customization and reduced production times. Manufacturers can now rapidly prototype and iterate designs, fostering a culture of innovation and leading to faster adoption of novel solutions in industries ranging from automotive to aerospace. The continuous evolution of these technologies underscores the significant role hydraulic pistons play in enhancing system performance while meeting stringent environmental and efficiency standards.

Future Trends: The Evolution of Hydraulic Pistons in Industrial Applications

The evolution of hydraulic pistons is critical to understanding modern industrial applications and their future trajectory. As industries continue to demand more efficiency and precision, hydraulic pistons have become increasingly sophisticated, enabling enhanced performance in a variety of machinery. Their adaptability allows them to meet the requirements of diverse sectors, from automotive to construction and beyond.

Future trends indicate that the integration of smart technologies will shape the development of hydraulic pistons. Sensors and IoT capabilities are anticipated to be embedded within piston systems, allowing for real-time monitoring and predictive maintenance. This advancement will not only enhance the reliability of equipment but also significantly reduce downtime and associated costs.

Moreover, there is a growing focus on sustainability in hydraulic systems. Innovations aimed at reducing energy consumption and using eco-friendly fluids are becoming essential as industries strive to minimize their environmental impact. As hydraulic piston technology continues to evolve, the focus on both efficiency and sustainability will likely drive the next generation of industrial applications, paving the way for smarter and greener production methods across various sectors.