Unlocking Efficiency: The Essential Guide to Hydraulic Rams for Global Buyers

In today's fiercely competitive global market, businesses are constantly seeking innovative solutions to enhance operational efficiency. One such solution that has gained significant traction is the use of hydraulic rams. These powerful devices, integral to various machinery and applications, provide the essential force needed to lift, push, and pull heavy loads with minimal effort. As industries from construction to manufacturing increasingly rely on hydraulic technology, understanding the nuances of hydraulic rams becomes crucial for global buyers aiming to maximize productivity and cost-effectiveness.

This guide delves into the essential aspects of hydraulic rams, offering valuable insights for decision-makers seeking to harness their full potential. From understanding the mechanics and types of hydraulic rams to identifying reliable suppliers and optimizing their use in different applications, this comprehensive resource aims to equip readers with the knowledge necessary to make informed purchasing decisions. As we unlock the efficiency provided by hydraulic rams, businesses can not only streamline their operations but also position themselves strategically within the marketplace for sustained growth and success.

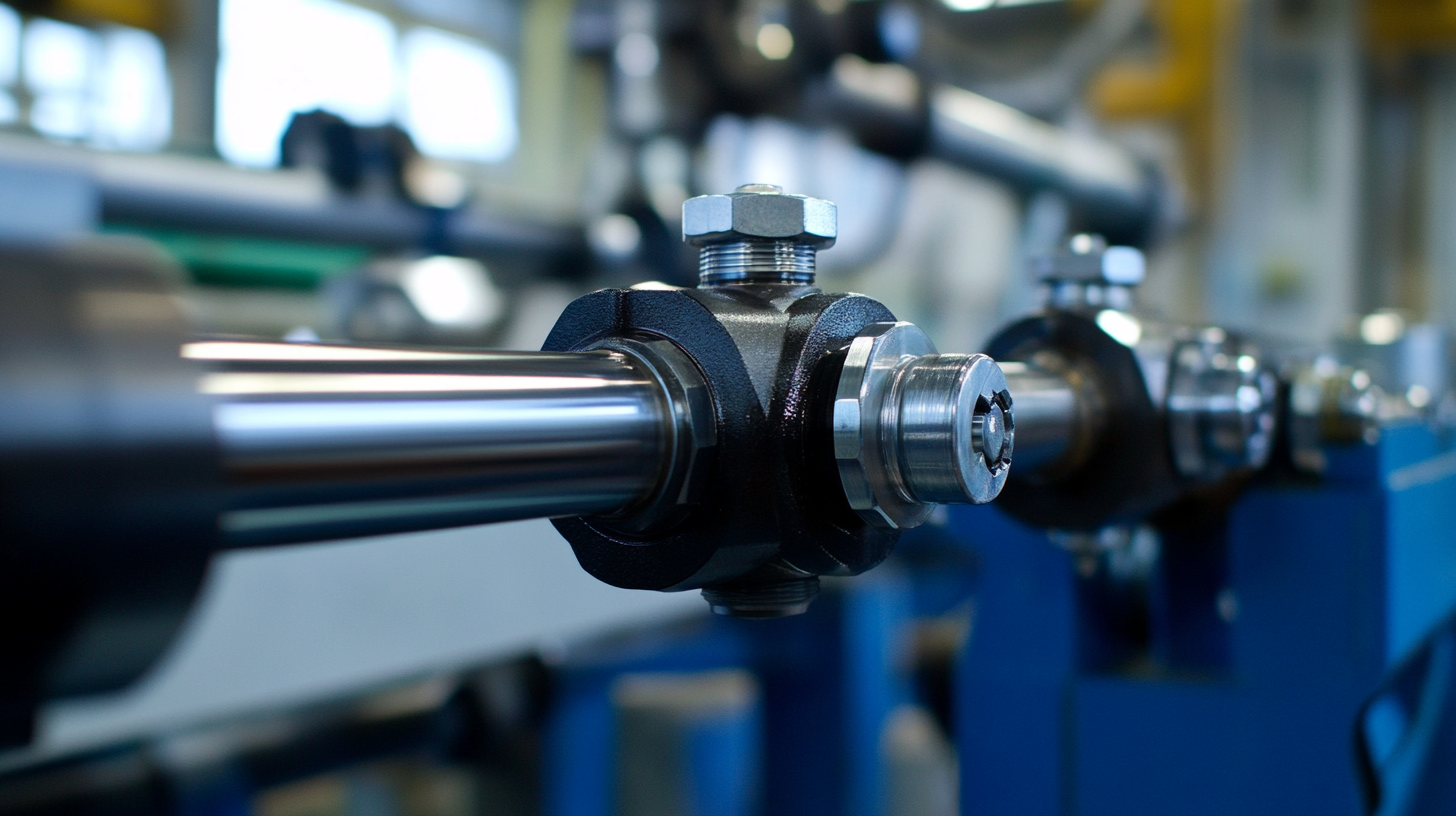

Understanding the Basics of Hydraulic Rams: Function and Types

Hydraulic rams are essential components in various industrial applications, acting as a powerhouse that transforms hydraulic energy into mechanical work. At their core, these devices consist of a cylinder and a piston. When hydraulic fluid is directed into the cylinder, it pushes the piston, generating force that can lift heavy loads or perform numerous tasks efficiently. Understanding the basics of hydraulic rams involves recognizing their key functions and the various types available, each tailored for specific operations and environments. The two primary types of hydraulic rams include single-acting and double-acting rams. Single-acting rams operate on one side of the piston, using hydraulic pressure to lift loads on the upward stroke, while relying on gravity or a spring system for the return stroke. This design is often simpler and more cost-effective, making it suitable for applications with less demanding return requirements. On the other hand, double-acting rams utilize hydraulic pressure on both sides of the piston, enabling more controlled and powerful movements in both directions. This versatility is particularly advantageous in jobs requiring precise positioning and repeatable actions. Incorporating advanced control systems, such as PWM (Pulse Width Modulation) controllers, can further enhance the efficiency and precision of hydraulic ram operations. As technology evolves, these controllers allow for finer adjustments in hydraulic fluid flow and pressure, optimizing performance for specific tasks. This integration not only maximizes the effectiveness of hydraulic rams but also aligns with the global shift towards automation and energy efficiency in industrial processes.

Key Applications of Hydraulic Rams in Various Industries

In various industries, hydraulic rams play a crucial role as they significantly enhance operational efficiency and productivity. These versatile mechanisms are pivotal in sectors ranging from construction and manufacturing to agriculture and automotive. Their applications are diverse, including lifting heavy loads, precise positioning, and powering essential machinery, thereby highlighting their importance in modern industrial processes. As companies continue to embrace industrial automation, the demand for hydraulic rams is expected to rise, reflecting the broader growth in the hydraulic cylinder market.

Recent developments indicate that the global hydraulic cylinder market is anticipated to grow at a moderate CAGR, with projections estimating a market valuation of approximately $22 billion by 2032. This growth is fueled by ongoing advancements in technology and a greater emphasis on automation across various sectors. Manufacturers are now introducing innovative hydraulic cylinders equipped with features such as high-precision detection systems, allowing for improved accuracy and operational control. These innovations not only streamline operations but also contribute to cost savings and enhanced productivity.

Additionally, companies are responding to industry demands by expanding their capabilities, with several manufacturers investing in new technologies and facilities. This proactive approach ensures that they remain competitive and meet the evolving needs of their customers. As industries adopt more sophisticated hydraulic solutions, the essential guide to hydraulic rams will serve as a valuable resource for global buyers, helping them navigate the myriad applications and benefits these systems offer.

Factors to Consider When Sourcing Hydraulic Rams Globally

When sourcing hydraulic rams on a global scale, several critical factors must be evaluated to ensure efficiency and effectiveness. First and foremost, understanding regional specifications and industry standards is essential. Different countries may have varied certifications for hydraulic equipment, so it is vital to verify that the products meet local regulations to avoid complications during the import process. This not only helps in ensuring safety but also aids in maintaining operational integrity within the target market.

Another significant consideration is the reputation and reliability of manufacturers. Engaging with well-established companies that have a track record of quality can mitigate risks associated with sourcing. It is advisable to conduct thorough research, including reading customer reviews and seeking testimonials. Additionally, direct communication with manufacturers can provide insights into their production processes and quality control measures, fostering a sense of trust and reliability.

The aspect of logistics cannot be overlooked in the sourcing process. Understanding shipping times, costs, and customs procedures plays a crucial role in maintaining a smooth supply chain. Establishing strong relationships with logistics partners can streamline these operations, ensuring that hydraulic rams arrive promptly and in optimal condition. Additionally, considering the implications of currency fluctuations and exchange rates will help in budgeting and financial planning for purchases.

Evaluating Quality and Reliability in Hydraulic Ram Suppliers

In the world of hydraulic systems, the reliability and quality of hydraulic rams are paramount for global buyers. A recent study highlights the critical role that oxidation wear plays in the failure mechanisms of piston cylinders. According to research published in the Journal of Hydraulic Engineering, over 30% of hydraulic ram failures can be attributed to oxidation wear, emphasizing the necessity for meticulous evaluation of suppliers based on their ability to produce high-quality components.

When selecting a hydraulic ram supplier, it's essential to examine their manufacturing processes and material choices. Reports from the International Society for Fluid Power highlight that suppliers utilizing advanced materials and coatings significantly reduce wear and increase the lifespan of hydraulic rams by up to 40%. This not only enhances performance but ultimately leads to greater operational efficiencies. Buyers must inquire about the supplier’s testing protocols, as rigorous quality assurance methods can further ensure that the components endure harsher operating conditions.

Moreover, establishing transparent communication with suppliers about their maintenance recommendations can be beneficial. A survey conducted by the Hydraulic Institute found that nearly 25% of hydraulic system failures were linked to inadequate maintenance and overlooked wear indicators. This presents a clear opportunity for informed buyers to engage with suppliers who prioritize not only the quality of their products but also offer comprehensive support that extends beyond the initial purchase, ensuring long-term reliability and efficiency in hydraulic operations.

Future Trends in Hydraulic Ram Technology and Market Demands

The hydraulic ram market is poised for substantial growth as industries increasingly recognize the efficiency and reliability these devices offer. According to a report by MarketsandMarkets, the global hydraulic ram market is projected to expand at a CAGR of 4.8%, reaching an estimated valuation of $2.6 billion by 2026. This surge is driven by rising demand across various sectors, including construction, agriculture, and manufacturing, where hydraulic rams are integral for powering machinery, transferring loads, and providing lifting solutions.

One of the most notable trends in hydraulic ram technology is the incorporation of IoT (Internet of Things) capabilities, which has transformed operational efficiency and predictive maintenance. The ability to monitor the performance of hydraulic rams in real time leads to significantly reduced downtime and maintenance costs. A study published by the International Journal of Advanced Manufacturing Technology revealed that companies employing IoT-enabled hydraulic systems reported a 30% improvement in productivity and a 25% reduction in operational costs.

Moreover, the move towards sustainability is influencing market demands, with an increasing emphasis on energy-efficient solutions in hydraulic ram design. The use of eco-friendly hydraulic fluids and the advancement of energy recovery systems are becoming pivotal. A research report from Grand View Research indicates that the demand for eco-efficient hydraulic systems is expected to grow by over 5% annually, reflecting a shift in buyer preferences toward environmentally responsible technologies. As global buyers navigate these evolving trends, the successful adoption of innovative hydraulic ram technologies could significantly enhance operational effectiveness and mitigate environmental impact.