The Complete Blueprint to Mastering Hydraulic Cylinder Service

In the world of industrial machinery and equipment, hydraulic systems play a critical role, with hydraulic cylinders being integral to numerous applications. According to a report by Research and Markets, the global hydraulic cylinder market is projected to reach USD 17.52 billion by 2027, reflecting the growing importance of efficient hydraulic cylinder service and maintenance in various sectors, including construction, manufacturing, and automotive. Mastering hydraulic cylinder service is vital not only for enhancing equipment performance but also for preventing costly downtimes associated with cylinder failures. This blog aims to provide a complete blueprint to mastering hydraulic cylinder service, equipping professionals with the knowledge and skills needed to optimize the lifespan and efficiency of hydraulic systems in their operations.

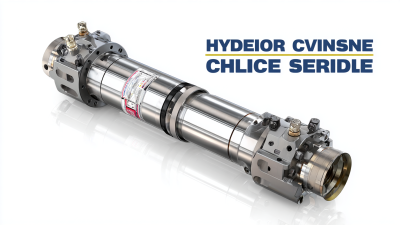

Essential Tools and Equipment for Hydraulic Cylinder Maintenance

Hydraulic cylinder maintenance is crucial for keeping equipment running efficiently and preventing costly downtime. Essential tools and equipment play a significant role in ensuring that hydraulic systems function optimally. Modern hydraulic systems often incorporate advanced technologies, such as sensors, that enable predictive maintenance strategies. A recent report highlighted that implementing such technologies can reduce unplanned downtime by up to 30%, underscoring the importance of staying ahead of maintenance needs.

Additionally, using the right maintenance tools can significantly improve efficiency. For instance, all-in-one hydraulic tool solutions allow field technicians to perform repairs more swiftly and effectively. It's critical to have a complete set of hydraulic maintenance tools that cater to various needs, from crimping tools to diagnostic equipment. Industry insights suggest that proper maintenance not only extends the lifespan of hydraulic cylinders but also enhances overall performance, making it essential for businesses relying on hydraulic machinery to invest in quality tools and equipment. With ongoing innovations in the hydraulic sector, staying equipped with the latest technology and tools can lead to substantial operational benefits.

The Essential Tools for Hydraulic Cylinder Maintenance

This bar chart illustrates the essential tools and equipment needed for the maintenance of hydraulic cylinders, showcasing their significance in the workflow.

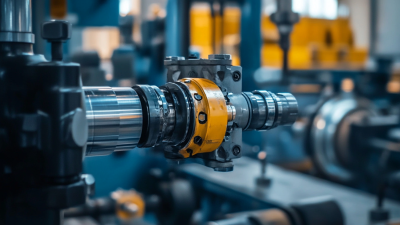

Step-by-Step Guide to Disassembling a Hydraulic Cylinder

Disassembling a hydraulic cylinder can seem daunting, but with a systematic approach, it becomes manageable and straightforward. Begin by ensuring you have a clean, organized workspace equipped with the necessary tools such as wrenches, screwdrivers, and a press if needed. Before starting, always take safety precautions: wear protective gear and release any hydraulic pressure within the cylinder to prevent accidents during disassembly.

Once you're prepared, the first step is to carefully remove any external components such as mounting brackets and hoses. Document each part's position and orientation to facilitate reassembly. Next, remove the end caps of the cylinder. Depending on the design, this may involve unscrewing bolts or carefully prying them off. After the caps are out, you can access the piston assembly inside. Gently pull out the piston rod, taking care to keep track of seals and bearings, as these are critical for the cylinder's functionality. With everything out, inspect each component for wear and damage, which will inform your repair or replacement decisions. Following these steps methodically will ensure a smooth disassembly and pave the way for effective service of your hydraulic cylinder.

Common Issues and Troubleshooting Tips for Hydraulic Cylinders

When it comes to hydraulic cylinders, understanding common issues is crucial for maintaining efficiency and prolonging service life. Leaking seals are a frequent problem that can lead to reduced performance. To troubleshoot this, inspect the seals for wear and consider replacing them if you notice any damage. Additionally, ensure that the cylinder is not over-pressurized, as excessive pressure can exacerbate leakage.

Another common issue is cylinder drift, which can compromise the precision of your hydraulic system. This often occurs when there is internal leakage through the piston or rod seals. A helpful troubleshooting tip is to perform a thorough inspection of the cylinder under operational conditions. Look for signs of fluid escaping and check the hydraulic fluid levels. If necessary, recalibrate your system or replace worn components to restore proper function. Regular maintenance checks and prompt attention to these issues can significantly enhance the reliability of hydraulic cylinders, ensuring smooth operation for your machinery.

Best Practices for Reassembling and Testing Hydraulic Cylinders

Reassembling and testing hydraulic cylinders is a crucial step in ensuring their longevity and optimal performance. According to a 2022 report from the International Fluid Power Society, approximately 85% of hydraulic cylinder failures can be traced back to improper assembly and maintenance practices. When reassembling, it is vital to meticulously inspect all components for wear and damage. Utilizing OEM (Original Equipment Manufacturer) parts can significantly reduce the risk of malfunction due to mismatched specifications.

Moreover, after reassembly, thorough testing is essential to validate the hydraulic system's performance. The same report indicates that proper testing can identify leaks, cylinder drift, and seal failures, which are critical indicators of potential issues. Implementing a standardized testing procedure, such as verifying the operating pressure and conducting function tests, can enhance the reliability of hydraulic systems. Organizations that prioritize these best practices not only extend the life of their equipment but also increase overall safety and efficiency in operations, with studies showing a 30% reduction in downtime attributed to proactive maintenance strategies.

Preventive Maintenance Tips to Extend Hydraulic Cylinder Lifespan

Hydraulic cylinders play a crucial role in various industries, including construction and manufacturing. Regular preventive maintenance is essential for extending their lifespan and ensuring operational efficiency. According to a report by the International Fluid Power Society, 30-50% of hydraulic system failures are related to improper maintenance practices. Implementing a structured maintenance program not only reduces downtime but also boosts productivity.

Hydraulic cylinders play a crucial role in various industries, including construction and manufacturing. Regular preventive maintenance is essential for extending their lifespan and ensuring operational efficiency. According to a report by the International Fluid Power Society, 30-50% of hydraulic system failures are related to improper maintenance practices. Implementing a structured maintenance program not only reduces downtime but also boosts productivity.

One key strategy for preventive maintenance is regular inspection. Operators should check for leaks, corrosion, and wear on the seals and rods. The National Fluid Power Association recommends scheduling these inspections every 500 operating hours or at least every six months. Additionally, maintaining optimal fluid levels and ensuring the hydraulic fluid is in good condition can prevent premature wear and tear. The American Society of Mechanical Engineers suggests using high-quality filtration systems, as they can remove particles as small as 1 micron, greatly improving the health of hydraulic systems.

Moreover, keeping cylinders properly lubricated is essential to avoid friction and overheating. Using the appropriate lubricants as per the manufacturer's recommendations is vital; improper lubrication can shorten the life of hydraulic components by up to 70%, according to a study by the Hydraulic Industry Standards Committee. By following these preventive maintenance tips, industries can enhance the performance and reliability of their hydraulic cylinders.

Related Posts

-

Understanding Industry Standards: How to Choose the Best Hydraulic Cylinder Service for Your Needs

-

Essential Guide to Understanding Hydraulic Cylinder Parts: Key Components and Their Impact on Performance

-

Hydraulic Cylinder Rebuilders Shine at Canton Fair 2025 with Record International Attendance

-

Navigating the 2025 Tech Landscape: A Comprehensive Checklist for Optimal Hydraulic Cylinder Service

-

Innovative Strategies for Effective Hydraulic Cylinder Maintenance and Repair Solutions

-

Overcoming Common Challenges with High Pressure Hydraulic Cylinders: Solutions for Success