Overcoming Common Challenges with High Pressure Hydraulic Cylinders: Solutions for Success

In the realm of industrial applications, High Pressure Hydraulic Cylinders play a pivotal role in delivering the power and precision required for various tasks. However, these vital components are not without their challenges. Issues such as leaks, unexpected failures, and maintenance complexities can hinder operational efficiency and increase downtime costs. To navigate these common pitfalls, it is essential to understand the underlying causes and explore effective solutions tailored to high-pressure systems. This blog will delve into the most prevalent challenges faced by operators and engineers alike, offering actionable strategies to overcome them.

By implementing these solutions, businesses can enhance the reliability of their hydraulic systems, ensuring smoother operations and improved productivity across the board. Join us as we uncover the pathway to success with High Pressure Hydraulic Cylinders and empower organizations to achieve their goals with confidence.

Identifying Common Operational Issues in High Pressure Hydraulic Cylinders

High pressure hydraulic cylinders are essential in various industrial applications, but they often encounter several operational challenges that can impede performance. Common issues include leaks, excessive wear, and pressure fluctuations. These problems not only reduce efficiency but can also lead to significant downtime and increased maintenance costs. Identifying these issues early is crucial for maintaining the integrity of hydraulic systems and ensuring their long-term functionality.

Tips for success with high pressure hydraulic cylinders include regular maintenance checks to detect leaks before they escalate. Implementing a routine inspection of seals and connections can help mitigate wear and prevent operational failures. Additionally, using advanced sensor technologies for monitoring hydraulic valve and system performance can provide real-time data, enabling operators to proactively address pressure fluctuations and other anomalies.

Another effective strategy is to ensure proper fluid selection and regular fluid analysis. The right hydraulic fluid can reduce wear and improve the overall efficiency of the system. By being vigilant about these common challenges and taking proactive measures, operators can enhance the reliability and performance of high pressure hydraulic cylinders, leading to greater productivity and success in their operations.

The Importance of Regular Maintenance and Inspection for Longevity

Regular maintenance and inspection are crucial for the longevity of high-pressure hydraulic cylinders. These components are vital in various applications, from manufacturing machinery to construction equipment, where they endure significant stress and harsh conditions. A thorough inspection routine helps identify potential issues before they escalate, preventing costly repairs and downtime. Regular checks should include monitoring fluid levels, examining seals and fittings for wear, and ensuring proper alignment.

Additionally, scheduled maintenance allows for timely lubrication and servicing, which significantly reduces the risk of hydraulic failure. Implementing a proactive maintenance program not only extends the lifespan of hydraulic cylinders but also enhances overall system performance. By ensuring all components are functioning optimally, businesses can improve efficiency and safety in their operations. Regular maintenance checks, therefore, play an indispensable role in mitigating risks associated with high-pressure systems, ensuring they operate reliably for years to come.

Overcoming Common Challenges with High Pressure Hydraulic Cylinders: Solutions for Success - The Importance of Regular Maintenance and Inspection for Longevity

| Challenge | Possible Solution | Recommended Maintenance Frequency | Inspection Checklist |

|---|---|---|---|

| Seal Leakage | Regular seal replacement and lubrication | Every 6 months | Check for wear, inspect for oil leaks |

| Cylinder Misalignment | Regular alignment checks and adjustments | Monthly | Assess alignment, inspect mounting brackets |

| Cylindrical Wear | Replace worn components, use proper materials | Annually | Inspect cylinder rods and bores for scratches |

| Pressure Issues | Calibrate pressure gauges and check for obstructions | Quarterly | Check gauge accuracy; inspect hose fittings |

| Contaminated Fluid | Regular fluid testing and replacement | Every 3 months | Inspect fluid quality; check filtration system |

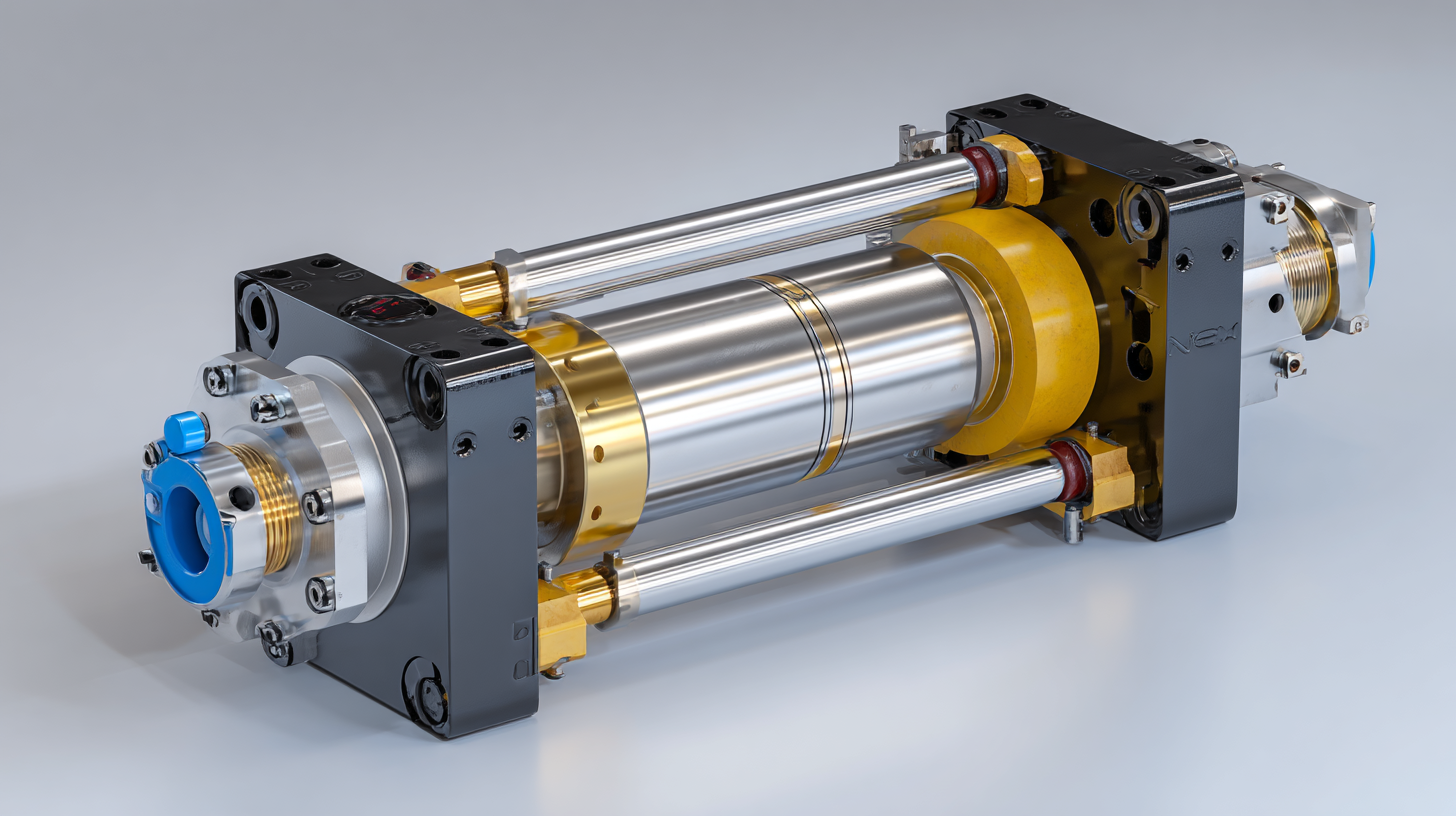

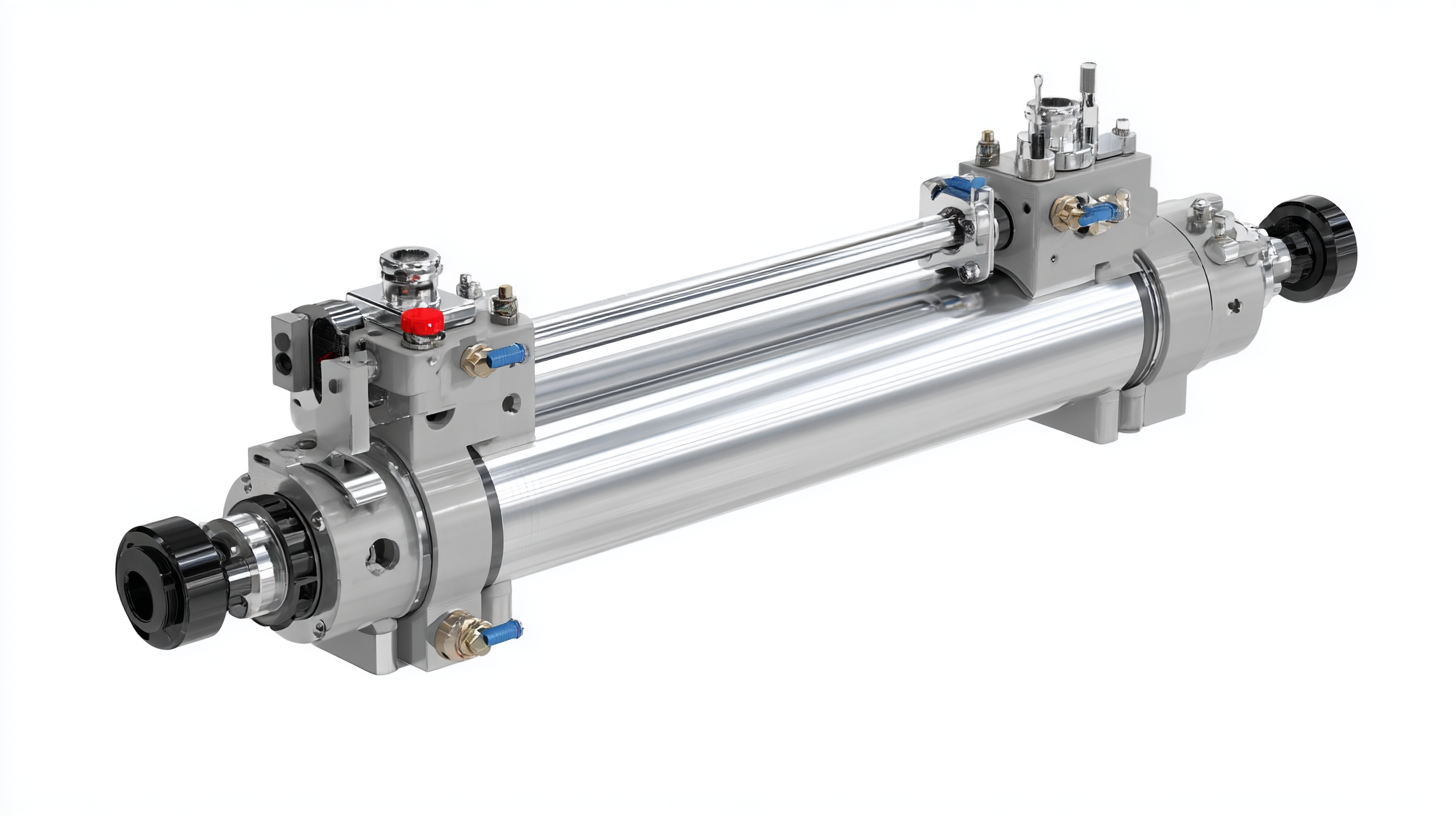

Innovative Design Solutions to Enhance Hydraulic Cylinder Performance

High pressure hydraulic cylinders play a crucial role in various industries, but they often face challenges that can hinder their performance. Innovative design solutions are essential to enhance the efficiency and reliability of these hydraulic components. One approach is the integration of advanced materials, which can improve strength while reducing weight. For example, using high-strength alloys or composite materials enables cylinders to withstand greater pressures without compromising their structural integrity, leading to longer service lives and reduced maintenance costs.

Another critical factor in enhancing hydraulic cylinder performance is optimizing the seal designs. High-quality seals prevent fluid leakage and contamination, which are common issues in high-pressure systems. Implementing modern sealing technologies, such as dynamic seals made from advanced elastomers or hybrid materials, can significantly improve sealing performance at elevated pressures and temperatures. Additionally, better design practices, such as proper alignment and compensating for thermal expansion, can further mitigate common challenges associated with hydraulic cylinder operation, ensuring smoother and more efficient functionality in demanding environments.

Overcoming Common Challenges with High Pressure Hydraulic Cylinders

This chart illustrates the performance enhancement achieved through innovative design solutions for high pressure hydraulic cylinders, focusing on key performance metrics like efficiency, durability, and maintenance needs.

Implementing Proper Fluid Selection to Reduce Hydraulic System Failures

The selection of the right fluid is critical in maximizing the performance and lifespan of high-pressure hydraulic cylinders. According to a report by the International Fluid Power Society, approximately 70% of hydraulic system failures are attributed to improper fluid choice or contamination. This highlights the necessity of considering fluid properties, such as viscosity, temperature stability, and lubricating capacities, to ensure optimal efficiency and system reliability.

For instance, the use of synthetic hydraulic fluids can significantly reduce wear and tear in high-pressure applications. The Society of Tribologists and Lubrication Engineers notes that synthetic fluids can offer superior thermal stability and improved lubrication under extreme pressures. By switching to these advanced fluids, companies can notably extend the operational life of their hydraulic systems while decreasing maintenance costs. Moreover, regular monitoring and testing of hydraulic fluid can prevent catastrophic failures and extend the service life of critical machinery. By prioritizing proper fluid selection, businesses can achieve significant operational efficiencies and mitigate the risk of downtime in their hydraulic systems.

Training and Safety Protocols to Minimize Risks in Hydraulic Operations

Hydraulic operations, particularly those involving high-pressure hydraulic cylinders, come with inherent risks that can impact safety and efficiency. According to a report by the International Association of Hydraulic Engineers, improper handling and lack of training account for over 30% of hydraulic system-related accidents. Therefore, implementing robust training and safety protocols is crucial for minimizing these risks. Comprehensive training programs should cover not only the operational techniques but also emergency response actions and the proper use of personal protective equipment (PPE).

Tip: Ensure that all personnel receive certification in hydraulic system operations to enhance their understanding of safety protocols. Regular refresher courses can help maintain a high standard of operational awareness among workers.

Moreover, establishing a culture of safety through consistent communication and adherence to safety protocols can significantly reduce the risk factors associated with hydraulic operations. According to the American Society of Safety Professionals, workplaces that implement strict safety measures see a 50% decrease in accidents. Regular safety audits and drills can prepare teams to handle potential emergencies efficiently.

Tip: Visual reminders, such as safety checklists and operational guidelines, should be displayed prominently in areas where hydraulic operations take place, reinforcing safe practices consistently.