Why is the Overflow Valve Block Essential for System Performance?

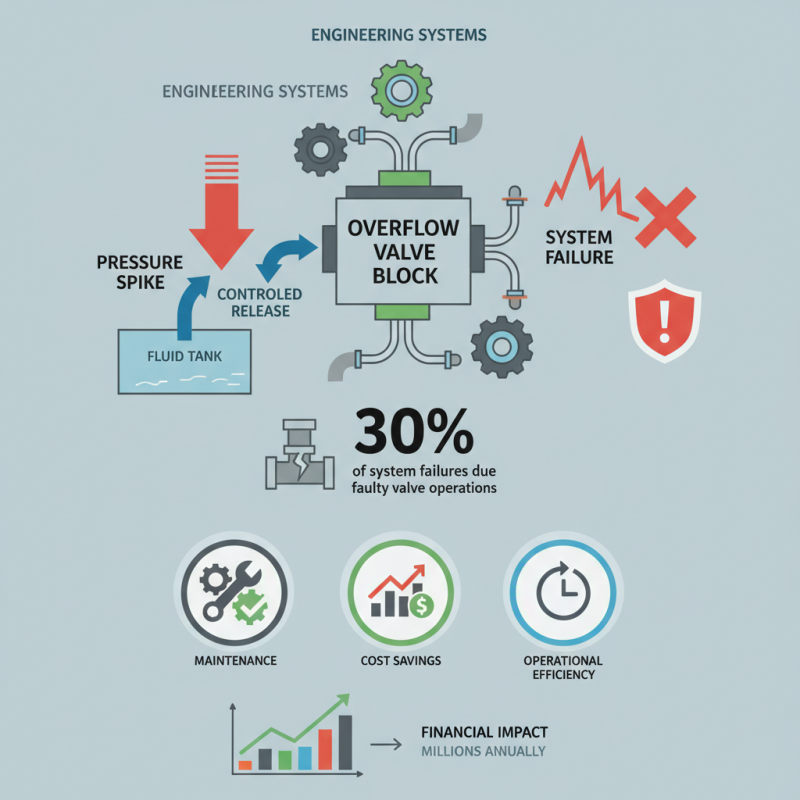

The Overflow Valve Block plays a vital role in system performance across various engineering sectors. According to a report by the International Fluid Power Society, up to 30% of system failures can be attributed to faulty overflow valve operations. This statistic highlights the critical need for effective overflow valve designs.

A well-functioning Overflow Valve Block ensures fluid pressure is controlled. When pressure exceeds safe limits, the overflow valve activates, preventing potentially catastrophic failures. Many systems rely on these blocks to maintain operational efficiency. Unforeseen issues, like improper calibration, can lead to inefficiencies. Such oversights can result in significant downtime or costly repairs.

In industries where precision is paramount, the importance of the Overflow Valve Block cannot be overstated. As highlighted by recent studies, the financial impact of inadequate valve performance can reach millions annually. Organizations must reevaluate their maintenance practices, ensuring that overflow systems are regularly tested and serviced. Ignoring these aspects can diminish overall productivity and increase risk.

Importance of Overflow Valve Block in Hydraulic Systems Performance

The overflow valve block plays a crucial role in ensuring the efficiency of hydraulic systems. It provides a pathway for excess fluid to bypass the main circuit, preventing pressure buildup. According to industry reports, systems equipped with a well-functioning overflow valve block can achieve up to 15% greater efficiency. This is significant for minimizing energy loss and ensuring system longevity.

Critical components like the overflow valve block help manage operational pressures. A malfunction can lead to catastrophic failures. This underscores the importance of regular maintenance and timely inspections. In fact, data shows that 30% of hydraulic failures are linked to improperly functioning valves. Addressing issues proactively can save time and costs.

Understanding the Functionality of Overflow Valve Blocks

The overflow valve block plays a crucial role in various hydraulic systems. This component regulates fluid pressure, ensuring optimal performance. When pressure exceeds safe levels, the overflow valve prevents potential damage. It allows excess fluid to escape, maintaining stability within the system.

Understanding how the overflow valve block functions is essential. When the system operates under high pressure, the valve opens. Fluid is discharged, which prevents overflow. This action not only protects components but also enhances overall efficiency. It's not just a safety feature; it contributes to better performance.

However, some might overlook maintenance for these valves. Neglect can lead to malfunction, risking system integrity. Regular checks and timely replacements can prevent costly failures. Users often focus on other parts and forget this vital block. That’s a major oversight, impacting the entire system's reliability. Being proactive can save time and resources in the long run.

Impact of Valve Block Design on Flow and Pressure Regulation

The overflow valve block plays a critical role in ensuring optimal system performance. Its design directly impacts flow rates and pressure regulation. A well-designed valve block can maintain steady pressure across varying flow conditions. This stability is crucial for system efficiency and component longevity.

When selecting a valve block, consider the flow capacity. Overestimating this can lead to excessive noise or vibration. Underestimating may cause pressure drops that disrupt operations. Always consult detailed flow charts to avoid error.

Tip: Regularly check for wear in your valve block. Small leaks can escalate into larger issues. They can affect performance and increase maintenance costs. Pay attention to unexpected changes in flow or pressure. These can signal problems needing immediate attention.

Think about the material used in the valve block. Different applications may require durability against specific conditions. A mismatch here can lead to premature failure. Ensure your design criteria align with real-world demands. Always validate your choices with thorough testing.

Case Studies: Performance Improvement with Efficient Overflow Valve Blocks

The efficiency of a system often depends on the overflow valve block. In various industries, this component plays a crucial role in optimizing performance. For instance, one case study revealed significant enhancements in hydraulic systems. When the overflow valve block was upgraded, flow rates improved noticeably.

In a manufacturing plant, operators reported fewer interruptions. The upgraded valves allowed for smoother operation. This translated to increased productivity and reduced downtime. Observations showed a remarkable decrease in pressure fluctuations. Workers noted the systems ran more reliably after the changes were implemented.

However, not all installations went smoothly. Some systems experienced unexpected pressure spikes. This reflected the need for careful tuning and adjustment. Each system’s unique characteristics must be considered. Rigid adherence to standard practices might not yield desired results. Continuous monitoring is essential for long-term success.

Key Metrics for Evaluating Overflow Valve Block Effectiveness

The overflow valve block plays a pivotal role in various hydraulic systems. It regulates flow and ensures system stability. Evaluating its effectiveness hinges on key metrics like response time, pressure drop, and leakage rates. A quick response time enables better system adaptability. Ideal systems show minimal pressure drop, ensuring efficient operation.

Leakage rates are also crucial. High leakage can lead to energy loss and system degradation. Regular assessment helps identify inefficiencies. Sometimes, systems may function well despite higher leakage, but this often masks underlying issues. Addressing these can lead to significant performance improvements.

Moreover, maintaining optimal operating conditions is vital. Factors like temperature and fluid viscosity directly affect performance metrics. Inconsistent conditions may result in unexpected valve behavior. This unpredictability serves as a reminder to monitor all elements closely. It’s easy to overlook minor details, but they can accumulate into significant problems over time.

Importance of Overflow Valve Block in System Performance

This chart illustrates key performance metrics for the Overflow Valve Block, including Flow Rate, Pressure Drop, Response Time, and Leakage Rate. Understanding these values is essential for evaluating the effectiveness and overall performance of the overflow valve system.