Understanding the Mechanics: How Single Acting Hydraulic Cylinders Revolutionize Industrial Applications

In the ever-evolving landscape of industrial applications, the advent of the

Single Acting Hydraulic Cylinder has marked a significant

transformation in operational efficiency and design versatility. According to a report by

Transparency Market Research, the global hydraulic cylinder market

was valued at approximately USD 12.9 billion in 2020,

with a projected growth rate of 3.2% through 2027, driven

largely by innovations in hydraulic technology.

Single Acting Hydraulic Cylinders are pivotal in this growth,

characterized by their ability to perform tasks using fluid power to exert force in one direction

while returning to a neutral position through a spring mechanism or external forces. As industries

seek ways to enhance productivity and streamline operations, the adoption of these cylinders has

proven advantageous, offering reliability and simplicity in various applications—from material handling

to construction equipment. Understanding the mechanics behind Single Acting Hydraulic Cylinders

is essential for embracing their full potential in modern industrial settings.

Single Acting Hydraulic Cylinders are pivotal in this growth,

characterized by their ability to perform tasks using fluid power to exert force in one direction

while returning to a neutral position through a spring mechanism or external forces. As industries

seek ways to enhance productivity and streamline operations, the adoption of these cylinders has

proven advantageous, offering reliability and simplicity in various applications—from material handling

to construction equipment. Understanding the mechanics behind Single Acting Hydraulic Cylinders

is essential for embracing their full potential in modern industrial settings.

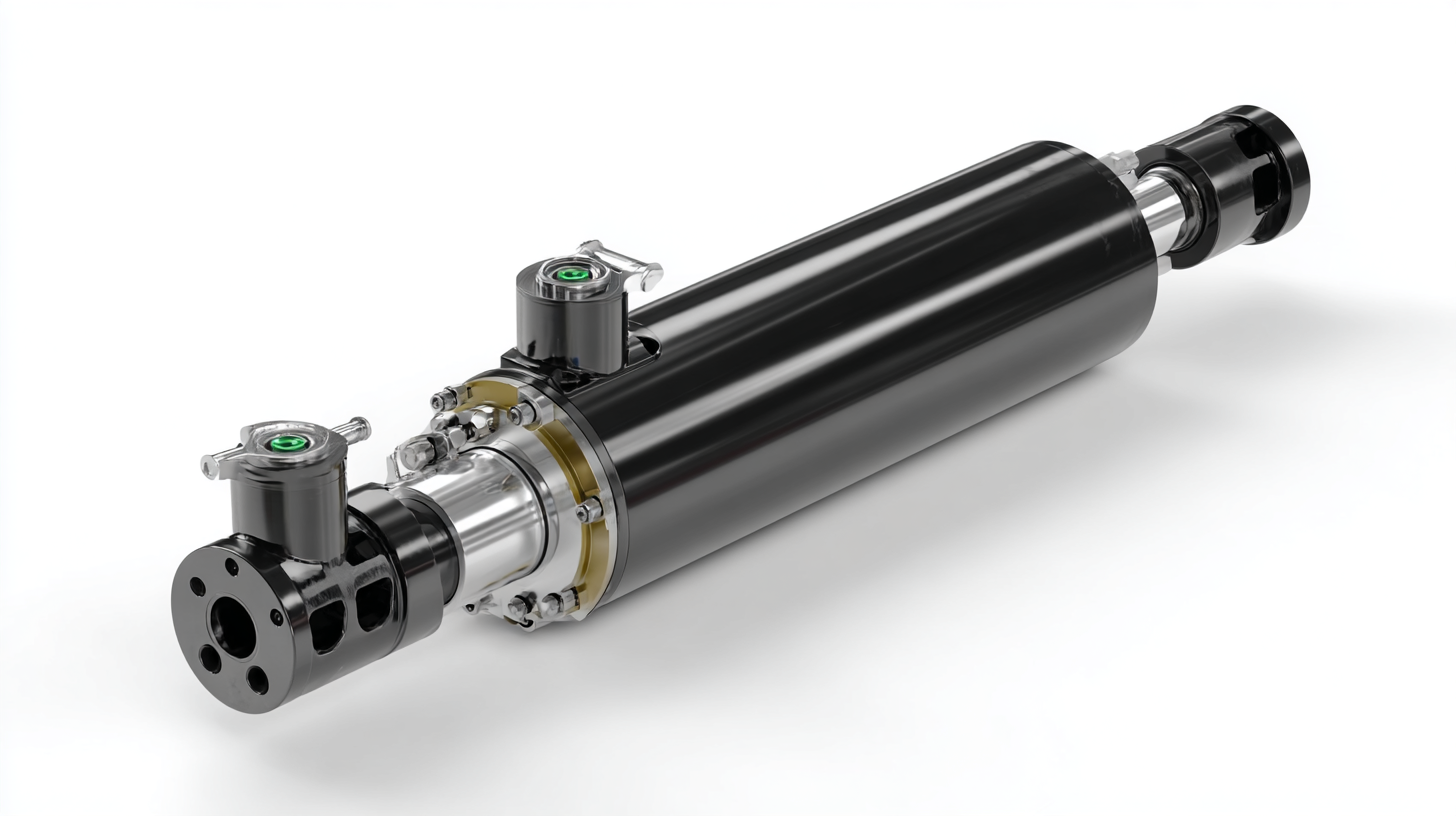

The Core Principles of Single Acting Hydraulic Cylinders

Single acting hydraulic cylinders are pivotal in the realm of industrial applications, primarily due to their straightforward design and effective force generation. These cylinders operate on the principle of hydraulic pressure, enabling movement in a single direction. When fluid is pumped into the cylinder, it extends, pushing the rod out. The return motion relies on external forces, such as gravity or springs, making them efficient for operations where the retracting force is naturally available. This mechanism simplifies the design and reduces the need for complex systems, ensuring cost-effectiveness.

**Tips:** When selecting single acting hydraulic cylinders for your operations, consider the load requirements and the necessary return mechanism. Understanding the operational environment is crucial, as factors like temperature and potential exposure to contaminants can influence cylinder performance. Additionally, regular maintenance checks will prolong the life of the cylinder and ensure consistent operation.

The core principle behind these cylinders lies in Pascal's Law, which states that pressure applied to a confined fluid is transmitted undiminished in all directions. This principle is vital for ensuring precise control in applications ranging from agricultural machinery to manufacturing equipment. By harnessing the power of hydraulic pressure, single acting cylinders not only enhance efficiency but also streamline workflows in various industrial settings.

Understanding the Mechanics: How Single Acting Hydraulic Cylinders Revolutionize Industrial Applications

| Dimension | Description | Application | Advantages |

|---|---|---|---|

| Bore Size | The diameter of the cylinder bore | Construction Manufacturing |

Greater force output |

| Stroke Length | The distance the piston travels | Automated machinery | Efficiency in space usage |

| Operating Pressure | Maximum pressure in the hydraulic system | Heavy machinery | Increased reliability |

| Weight Capacity | The maximum weight it can lift | Material handling | Safety in operations |

| Cycle Time | Time taken for a complete hydraulic cycle | Manufacturing lines | Improved productivity |

Key Applications in Modern Industries Utilizing Hydraulic Technology

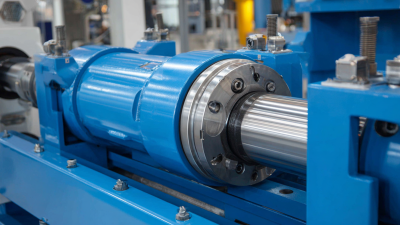

Single acting hydraulic cylinders play a crucial role in modern industrial applications, significantly enhancing efficiency and productivity across various sectors. According to a 2022 report by the International Fluid Power Society, industries utilizing hydraulic technologies have reported a 30% increase in operational efficiency due to the compact and robust design of single acting cylinders. These cylinders are particularly beneficial in applications where space is limited, as they provide powerful force with a simplified mechanism, allowing for effective operation in confined settings.

In construction, single acting hydraulic cylinders are vital in equipment such as cranes and excavators, enabling lifting and maneuvering heavy loads with precision. A 2023 market research report by Grand View Research revealed that the global hydraulic cylinder market is projected to reach $25 billion by 2028, largely driven by demand in construction and manufacturing sectors.

Moreover, the automotive industry also leverages these cylinders for tasks ranging from clamping in assembly lines to lifting vehicles for maintenance, highlighting their versatility and reliability in modern manufacturing processes. As industries continue to adopt advanced hydraulic technologies, the role of single acting hydraulic cylinders is set to expand, further revolutionizing operational capabilities.

Advantages of Single Acting Cylinders Over Other Types

Single acting hydraulic cylinders have emerged as a pivotal technology in various industrial applications, primarily due to their unique advantages over other types of cylinders. One of the most significant benefits is their simplicity in design. These cylinders use hydraulic pressure to extend the piston in one direction and rely on a spring or external forces to retract. This straightforward mechanism not only reduces the overall weight of the system but also minimizes maintenance requirements. Businesses can enjoy increased reliability and lower operational costs, making single acting cylinders an attractive option for many industries.

**Tips:** When considering single acting hydraulic cylinders, it’s crucial to assess the application requirements. Ensure that the force needed to retract the cylinder can be adequately supplied by a spring or gravity, as this will affect overall system performance. Additionally, evaluate the environment they will be used in to ensure compatibility with the materials used in the cylinder construction.

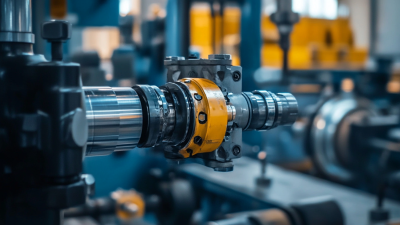

Another significant advantage is their efficiency in space utilization. Single acting cylinders require less operational space compared to double acting cylinders, making them ideal for compact applications. Their design allows for easier installation in tight spaces, thereby facilitating more extensive machinery layouts. This space efficiency can lead to better workplace ergonomics and safer operational environments, promoting a more productive workflow.

**Tips:** Always prioritize selecting a cylinder that fits the confined area without compromising on functionality. It’s beneficial to conduct thorough measurements and simulations to avoid any unexpected operational challenges.

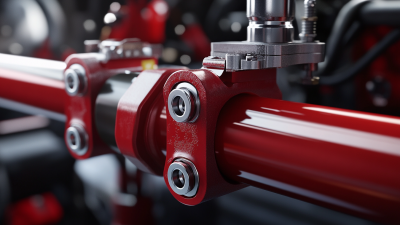

Tips for Optimizing Performance and Maintenance of Hydraulic Cylinders

Single acting hydraulic cylinders have become essential for various industrial applications due to their simplicity and efficiency. To ensure optimal performance, regular maintenance is crucial. According to a report by the International Fluid Power Society, routine checks on hydraulic oil levels and filter conditions can improve system uptime by up to 20%. This proactive approach minimizes the risk of hydraulic failure and prolongs the lifespan of the cylinders.

Another key aspect of optimizing performance lies in the correct sizing and application of hydraulic cylinders. The Hydraulic Institute highlights that using appropriately sized cylinders can lead to energy savings of approximately 15-30%, depending on the application. Additionally, ensuring seals and fittings are in good condition prevents leaks, which not only enhances performance but also reduces operational costs. Implementing these strategies can significantly enhance the functionality and reliability of single acting hydraulic cylinders in industrial settings.

Performance Comparison of Single Acting Hydraulic Cylinders in Various Applications

This bar chart illustrates the performance efficiency of single acting hydraulic cylinders utilized across different industrial applications, showcasing their impact on operational effectiveness in areas such as manufacturing, construction, and material handling.

Future Trends in Hydraulic Cylinder Innovations and Applications

The landscape of hydraulic cylinder technology is undergoing significant transformation, with the rise of single acting hydraulic cylinders driving innovative applications across various industrial sectors. According to a recent report by the International Hydraulics Association, the market for hydraulic cylinders is projected to grow by 4.5% annually, reaching $10 billion by 2027. This growth is largely fueled by advancements in cylinder design and materials, enabling greater efficiency and reliability in operations.

In addition to enhancing productivity, future trends point toward the integration of smart technologies into hydraulic systems. The implementation of IoT (Internet of Things) in hydraulic cylinders is emerging, allowing for real-time monitoring and predictive maintenance. This not only improves operational efficiency but also reduces downtime and maintenance costs. A study by TechSci Research indicates that the smart hydraulic cylinder market will increase by over 20% annually, highlighting a significant shift in industry practices aimed at optimizing hydraulic applications. As these innovations continue to evolve, industries will benefit from the enhanced performance and versatility that single acting hydraulic cylinders can provide.

Related Posts

-

Essential Guide to Understanding Hydraulic Cylinder Parts: Key Components and Their Impact on Performance

-

Top Strategies for Optimizing Your Best Hydraulic Cylinder System Performance

-

The Complete Blueprint to Mastering Hydraulic Cylinder Service

-

Innovative Strategies for Effective Hydraulic Cylinder Maintenance and Repair Solutions

-

Hydraulic Cylinder Rebuilders Shine at Canton Fair 2025 with Record International Attendance

-

Exploring Diverse Features and Applications of the Best New Hydraulic Cylinder Models