Essential Tips for Choosing the Right Hydraulic Ram Cylinder?

When selecting a Hydraulic Ram Cylinder, it’s essential to understand your specific needs. The right choice can significantly affect your machinery’s performance. There are various factors to consider, such as load capacity, stroke length, and working pressure.

Keep in mind that not all cylinders are created equal. Some may not meet the demands of heavy-duty tasks. Additionally, the material used can impact durability and efficiency. Pay attention to the details that count. A small oversight in your selection process can lead to inefficiencies and potential operational hazards.

Choosing the right Hydraulic Ram Cylinder may seem straightforward; however, it requires careful thought. Engaging with experts in the field can provide valuable insights. Yet, be aware that advice may vary, and not every suggestion will fit your application perfectly. Reflection on your choice is crucial for achieving optimal results.

Understanding the Basics of Hydraulic Ram Cylinders

Hydraulic ram cylinders are crucial components in various industries. They convert hydraulic energy into mechanical force. Understanding the basics can help you select the right one for your needs. A study from the Hydraulic Institute shows that improper selection can lead to a 30% decrease in efficiency.

When considering a hydraulic ram cylinder, pay attention to key specifications. Stroke length, bore diameter, and pressure ratings are vital. The wrong size can result in failure during operation. Research indicates that nearly 25% of equipment failures stem from inadequate cylinder specifications. Choose a cylinder that matches your system's requirements closely.

Also, consider the material and construction quality. Cylinders made from subpar materials may corrode quickly. Over time, this can lead to leaks and safety hazards. A report emphasizes that 40% of maintenance issues arise from corrosion-related failures. Understanding these details ensures you choose the best hydraulic ram cylinder for your application.

Essential Tips for Choosing the Right Hydraulic Ram Cylinder

| Feature | Description | Importance |

|---|---|---|

| Size | Choose a cylinder that fits the space and application requirements. | Ensures compatibility and optimal performance. |

| Weight Capacity | Check the maximum load the cylinder can handle. | Prevents system failure and accidents due to overload. |

| Stroke Length | Determine how far the cylinder needs to extend to perform effectively. | Essential for achieving desired movement and function. |

| Pressure Rating | Select a cylinder that operates within the pressure limits of your system. | Ensures reliability and longevity of the hydraulic system. |

| Material | Assess the material used for durability and compatibility with fluids. | Directly impacts the lifespan and efficiency of the cylinder. |

| Mounting Options | Check the types of mounts available and their suitability for your setup. | Affects ease of installation and operation. |

| Seal Type | Identify the seal design to prevent leaks and contamination. | Critical for maintaining performance and safety. |

Key Factors Influencing Hydraulic Ram Cylinder Selection

Choosing the right hydraulic ram cylinder requires careful consideration of several key factors. The load capacity is critical; it determines how much weight the cylinder can safely handle. Next, the cylinder stroke must be appropriate for your application. If it’s too short, your tasks may not be completed efficiently.

Another factor is the operating pressure. Each application requires specific pressure levels. Using a cylinder with inadequate pressure can lead to underperformance. Additionally, materials matter. Hydraulic cylinders made from the right materials resist wear and provide durability.

Size is important too. A cylinder too large may not fit in the intended space. Conversely, one that is too small can lead to failure. Take time to evaluate all these aspects. Mistakes in selection can be costly. Always review your options thoroughly. The perfect fit is crucial for optimal performance.

Essential Tips for Choosing the Right Hydraulic Ram Cylinder

Hydraulic Cylinder Sizing: Calculating Pressure and Load Requirements

When selecting a hydraulic ram cylinder, understanding how to size it properly is crucial. The pressure of the system plays a vital role. You need to consider the load requirements carefully. What will the cylinder lift? Weighing the load is the first step. Don’t forget to factor in any potential resistance or friction. Sometimes, we overlook these aspects, thinking they are minor.

You should utilize formulas to calculate the necessary pressure. The area of the piston and the load determine this pressure. A simple calculation can save you from choosing the wrong cylinder size. Ensure that the specifications match your application. It's easy to underestimate the force required, leading to disappointment. Reflect on your calculations; mistakes can occur. You want a cylinder that operates efficiently.

In some cases, individuals rush the selection process. Taking time to analyze all variables is essential. Neglecting small details can result in poor performance. A poorly sized cylinder can lead to overexertion or inefficiency. This is where thoughtful consideration of pressure and load becomes invaluable. Take a moment to revisit your data. Is it accurate? Is your cylinder truly the best fit for your needs?

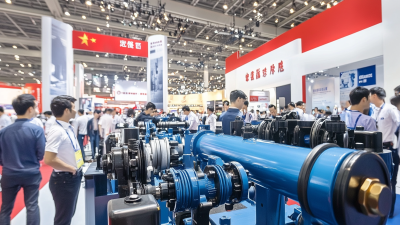

Types of Hydraulic Ram Cylinders and Their Applications

When selecting a hydraulic ram cylinder, understanding the types and their applications is crucial. Hydraulic cylinders come in various forms, each designed for specific functions. For example, single-acting cylinders are preferred for lifting tasks. They use hydraulic pressure for movement in one direction. On the other hand, double-acting cylinders can push and pull. This versatility makes them suitable for more complex applications.

Another type is the telescopic ram. These cylinders have multiple stages, allowing for extended reach in compact spaces. They are common in dump trucks and construction equipment. However, they require careful handling to avoid structural damage. Consider the weight and size of your loads when choosing a cylinder. Don't overlook these factors; they can impact efficiency.

Here are some tips to help you decide. Assess the space you have for installation. Ensure the cylinder fits easily. Look at the load capacity carefully. Overloading can lead to failure. It's wise to choose a cylinder rated for more than your maximum load. Regular maintenance is also essential. A well-maintained cylinder can last much longer and perform better than one neglected.

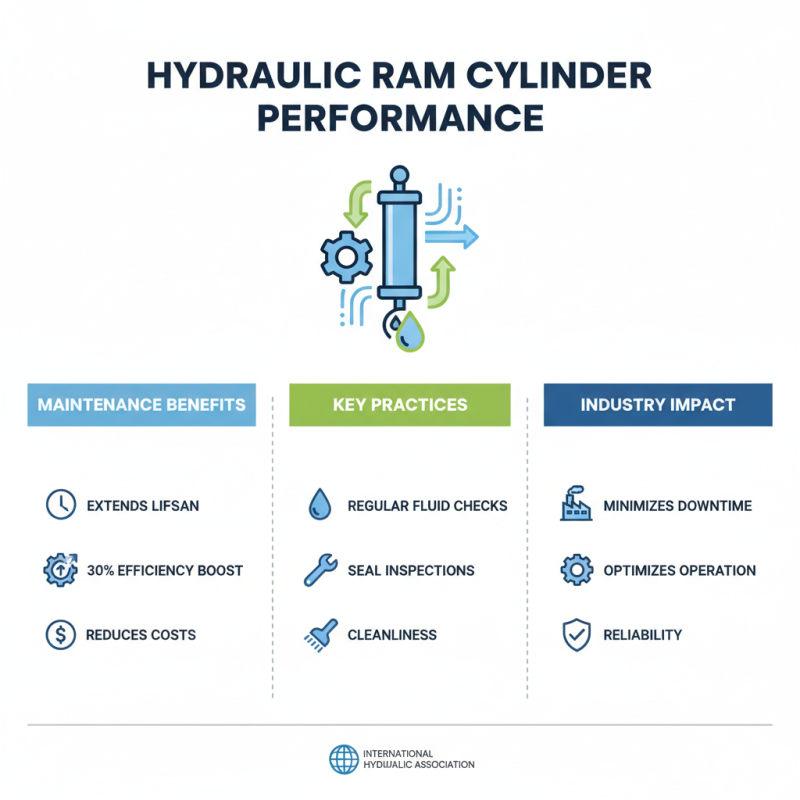

Maintenance Tips for Optimal Hydraulic Ram Cylinder Performance

Maintaining the optimal performance of hydraulic ram cylinders is crucial for many industries. Regular maintenance can extend the life of these vital components. According to a report by the International Hydraulic Association, proper care can improve efficiency by up to 30%. This is significant for minimizing downtime and reducing operational costs.

Tip: Clean the cylinder regularly. Dust and contaminants can significantly impact performance. A simple routine can prevent costly repairs.

Inspect seals and fluid levels frequently. Worn seals can lead to leaks, which waste fluid and reduce function. The Hydraulic Institute suggests that most failures stem from inadequate seal maintenance. Addressing these issues promptly is essential.

Tip: Monitor the operating temperature. Hydraulic fluids can break down if exposed to high heat. This reduces performance and can lead to complete failure. Keep a thermometer near your system to make adjustments if necessary.

Regularly reviewing performance metrics is also beneficial. Assessing pressure levels and response times can offer insights into potential problems. This proactive approach could save both time and money in the long run.

Related Posts

-

Revolutionizing Hydraulic Cylinder Systems The Ultimate Guide to 2025 Industry Innovations

-

How to Identify Top 7 Manufacturers of Hydraulic Cylinders for Global Buyers

-

Unveiling China's Manufacturing Might: The Era of Superior Hydraulic Cylinders

-

Top Strategies for Optimizing Your Best Hydraulic Cylinder System Performance

-

Hydraulic Cylinder Rebuilders Shine at Canton Fair 2025 with Record International Attendance

-

Leading Double Acting Hydraulic Cylinder Manufacturers from China at the 137th Canton Fair