The Ultimate Guide to Understanding Hydraulic Rams in Modern Engineering

Hydraulic Rams have become an indispensable component in modern engineering, playing a pivotal role in various applications ranging from construction to manufacturing. According to a recent industry report by Grand View Research, the global hydraulic equipment market is expected to reach $60 billion by 2025, with hydraulic systems, including rams, accounting for a significant portion of this growth. This surge is attributed to the increasing demand for efficient power transmission and the ongoing trend towards automation in industrial processes.

Hydraulic Rams operate on the principle of fluid mechanics, utilizing hydraulic fluid to generate force and movement, which allows them to handle heavy loads with precision and reliability. As engineers continue to innovate and enhance the efficacy of hydraulic systems, understanding the workings, applications, and advantages of Hydraulic Rams has never been more crucial for professionals eager to leverage this technology in their projects.

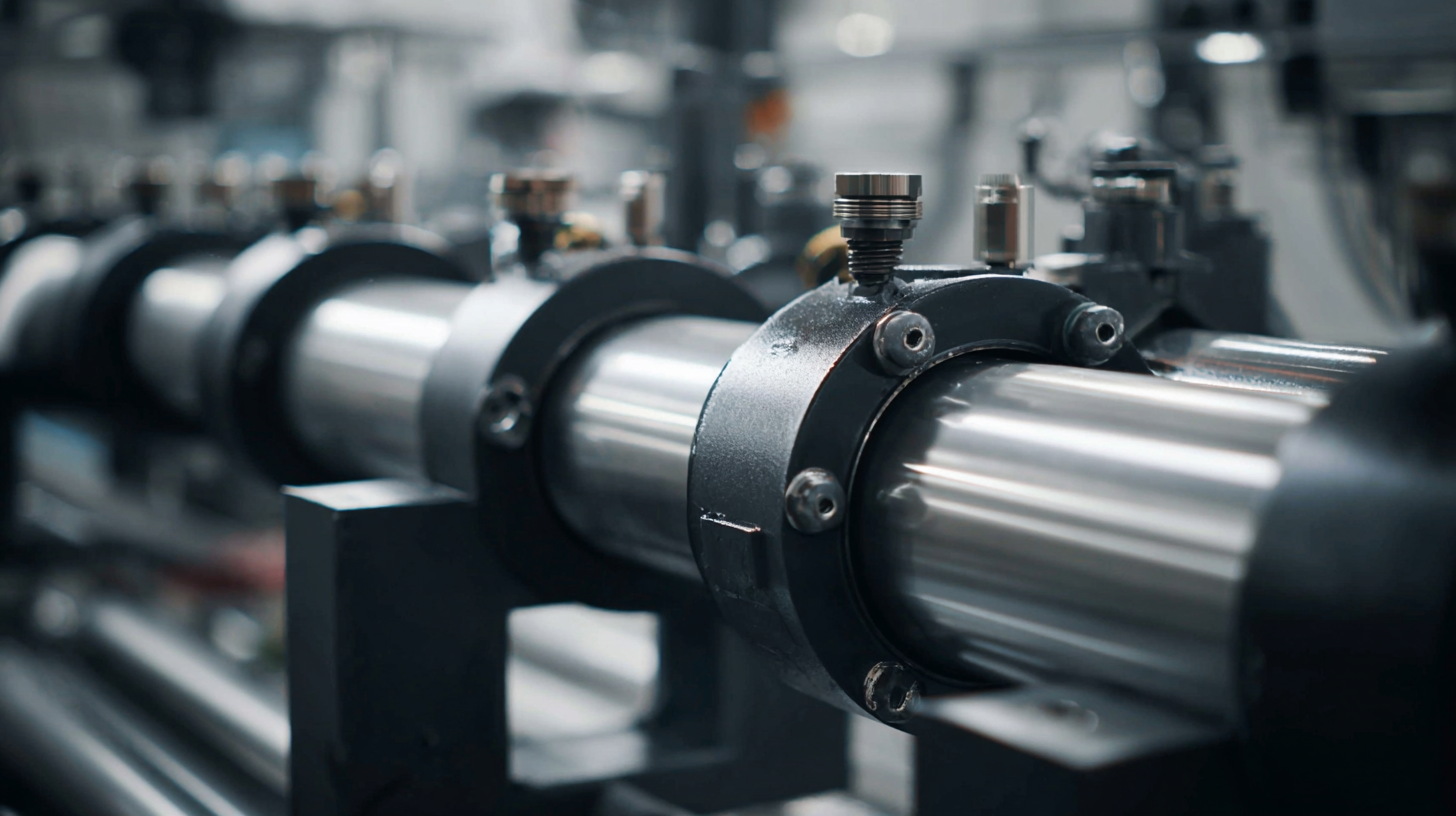

Understanding the Basics of Hydraulic Rams: Key Components and Functionality

Hydraulic rams are fundamental components in modern engineering, serving as essential tools in various applications, from construction to manufacturing. At their core, hydraulic rams utilize Pascal's principle, where pressure applied to a confined fluid generates force that is transmitted equally in all directions. This principle allows hydraulic rams to amplify force, making them particularly effective in lifting heavy loads. According to a report by the International Fluid Power Society (IFPS), hydraulic systems, including rams, account for approximately 30% of the market in industrial automation, underlining their importance in the engineering sector.

Key components of hydraulic rams include the cylinder, piston, and hydraulic fluid. The cylinder contains the piston, which moves through the fluid when pressure is applied. This movement translates into linear force, which can be harnessed for various applications, such as pushing, lifting, or compressing materials. The choice of hydraulic fluid also plays a crucial role in the efficiency and performance of the system; the latest studies indicate that the viscosity and density of the fluid can significantly affect the operational effectiveness, with optimal fluid characteristics yielding up to a 20% increase in efficiency. Understanding these fundamental aspects of hydraulic rams is essential for engineers aiming to design and implement more efficient systems in their projects.

The Role of Hydraulic Rams in Modern Construction Projects and Their Efficiency

Hydraulic rams play a pivotal role in modern construction projects, revolutionizing the way heavy materials are lifted and moved. These powerful mechanical devices utilize the principles of hydraulics to amplify force, allowing for the movement of extremely heavy loads with minimal manual effort. Their applications are vast, ranging from lifting large steel beams to maneuvering massive concrete slabs, making them indispensable in the construction of skyscrapers, bridges, and tunnels.

Moreover, the efficiency of hydraulic rams significantly enhances productivity on construction sites. Unlike traditional lifting methods that often require extensive manpower and time, hydraulic rams operate with precision and speed, reducing the risk of delays. Their ability to provide consistent and controlled movements minimizes the potential for accidents, ensuring a safer working environment. Additionally, the energy efficiency of hydraulic systems lends itself to sustainable construction practices, making them an ideal choice for modern engineering projects that prioritize both safety and environmental responsibility.

The Role of Hydraulic Rams in Modern Construction Projects

This chart illustrates key performance metrics of hydraulic rams used in modern construction projects, highlighting their efficiency, load capacity, installation time, maintenance cost, and lifespan.

Comparative Analysis: Hydraulic Rams vs. Pneumatic Cylinders in Engineering Applications

In modern engineering applications, both hydraulic rams and pneumatic cylinders play crucial roles, each offering distinct advantages suited to specific tasks. Hydraulic rams utilize incompressible fluid to generate force, providing high levels of power and precision. This makes them ideal for heavy lifting and industrial machinery where significant force is required. Their ability to maintain consistent force over long durations without fatigue is a notable benefit in demanding environments, such as construction and manufacturing.

On the other hand, pneumatic cylinders operate using compressed air, which allows for quicker movements and a lighter operational weight. This makes them highly effective in applications requiring rapid actuation, such as automation and robotics. The clean and safe nature of pneumatic systems, free from concerns of fluid leaks, further enhances their appeal in environments where cleanliness and safety are paramount. However, pneumatic cylinders generally offer less force compared to their hydraulic counterparts, which limits their use in heavy-duty applications. Thus, the choice between hydraulic rams and pneumatic cylinders largely depends on the specific requirements of the engineering task at hand, weighing factors such as force, speed, and operational environment.

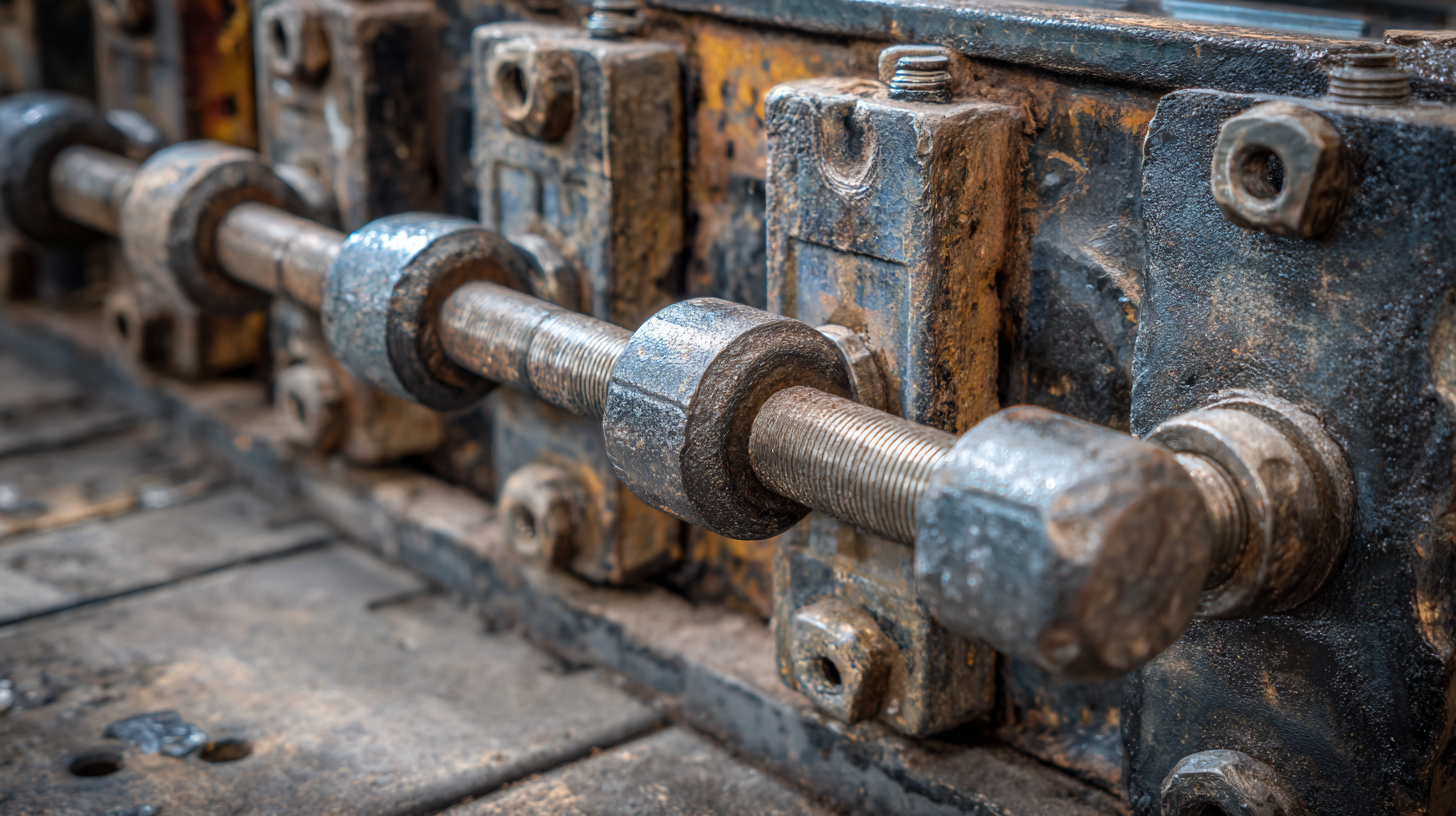

Key Maintenance Tips for Ensuring Longevity and Optimal Performance of Hydraulic Rams

Maintaining hydraulic rams is crucial for ensuring their longevity and optimal performance in engineering applications.

Regular inspection is essential; operators should check for leaks, wear, and corrosion. Any signs of fluid leakage should be addressed immediately, as this can indicate internal damage or seal failure.

It’s also vital to monitor the hydraulic fluid levels and replace the fluid according to the manufacturer's recommendations to prevent contamination and ensure efficient operation.

Another key maintenance tip is to lubricate the moving parts of the hydraulic ram regularly.

Proper lubrication reduces friction, minimizing wear and tear on components. Additionally, operators should periodically test the ram’s pressure and functionality to ensure it operates within designated parameters.

By implementing these maintenance practices, engineers can significantly extend the lifespan of hydraulic rams and maintain their performance, ultimately leading to more effective and reliable engineering solutions.

Innovative Applications of Hydraulic Rams in Renewable Energy and Automation Industries

Hydraulic rams have emerged as a pivotal technology in the realms of renewable energy and automation, offering innovative solutions that enhance efficiency and sustainability. In the renewable energy sector, hydraulic rams facilitate the conversion of hydraulic energy into mechanical work, playing a crucial role in systems like tidal energy generation and hydroelectric power plants. Their ability to harness and manipulate water pressure makes them ideal for driving turbines, which can produce clean energy while minimizing ecological footprints. Additionally, their robustness allows them to operate effectively in harsh environments, thus supporting the long-term viability of renewable projects.

In the automation industry, hydraulic rams are integral to various applications, from material handling to robotic systems. These devices provide the necessary force to lift and move heavy loads with precision, thereby streamlining production processes and improving safety. Their adaptability means they can be integrated into automated assembly lines, enhancing operational efficiency and reducing labor costs. As industries continue to prioritize automation and sustainability, the role of hydraulic rams will likely expand, making them a cornerstone of future innovations in these fields.

Related Posts

-

Unlocking Efficiency: Essential Insights for Sourcing High-Performance Hydraulic Rams Globally

-

Unlocking Quality Hydraulic Rams Choosing the Right Manufacturer for Global Sourcing Success

-

Ultimate Checklist for Choosing the Best Hydraulic Rams for Your Needs

-

Unleashing Excellence in Hydraulic Rams with Chinas Leading Manufacturing Power

-

Exploring the Top 5 Types of Best Hydraulic Rams for Global Procurement Professionals

-

Unlocking Efficiency: The Essential Guide to Hydraulic Rams for Global Buyers