Understanding Hydraulic Seals A Comprehensive Tutorial for Efficient Industrial Applications

In the realm of industrial applications, hydraulic seals play a pivotal role in ensuring the efficiency and reliability of machinery. According to a report by MarketsandMarkets, the global hydraulic seals market is projected to reach USD 7.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.2% from 2020 to 2025. This growth underscores the critical importance of hydraulic seals in various sectors, including construction, automotive, and aerospace, where they are essential for preventing fluid leaks and maintaining pressure. Understanding the intricacies of hydraulic seals is vital for engineers and maintenance professionals aiming to enhance equipment performance and minimize downtime. In this comprehensive tutorial, we will delve into the types, functions, and best practices for selecting and maintaining hydraulic seals, providing you with valuable insights to optimize your industrial applications.

The Importance of Hydraulic Seals in Industrial Machinery

Hydraulic seals play a crucial role in the efficiency and reliability of industrial machinery. According to a report by Research and Markets, the global hydraulic seals market is expected to reach USD 8.5 billion by 2026, reflecting the growing demand for hydraulic systems across various industries. These seals are essential in preventing fluid leaks, which can lead to decreased performance and increased operational costs. In fact, improper sealing can result in leaks that account for up to 20% of a machine’s overall operational expenses.

Moreover, the importance of hydraulic seals extends beyond just cost-saving measures. They also enhance the longevity and safety of machinery. Industry studies show that the right sealing solutions can reduce maintenance costs by up to 30% and prolong the lifespan of equipment significantly. With the rise of automation and more complex hydraulic systems in sectors like manufacturing and construction, investing in high-quality hydraulic seals is not just a necessity but also a strategic advantage for businesses aiming to improve their operational efficiency and minimize downtime.

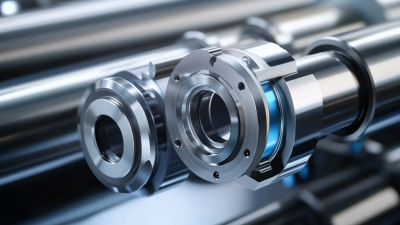

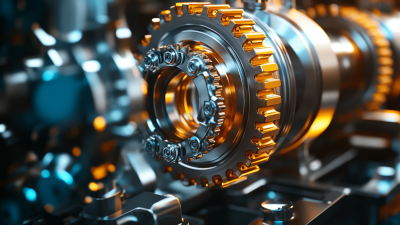

Types of Hydraulic Seals and Their Applications

Hydraulic seals play a crucial role in various industrial applications, ensuring efficiency and reliability in systems ranging from hydraulic cylinders to automotive components. The global hydraulic cylinder market was valued at approximately USD 14.3 billion in 2021 and is projected to grow to USD 18.3 billion by 2027. This growth highlights the increasing demand for advanced sealing solutions, which are fundamental to the performance of hydraulic actuators in machinery and modern aircraft. These seals must withstand harsh operating conditions while preventing leakage and wear, crucial for maintaining system integrity.

When examining the types of hydraulic seals, various materials and designs come into play. Common types include O-rings, rotary seals, and piston seals, each suited for specific applications. For example, nitrile butadiene rubber (NBR) and fluoroelastomers (FKM) are frequently utilized for their excellent resistance to oil and temperature variations. The oil seals market is also trending upwards, with projections indicating substantial growth in the coming years. As industries continue to innovate, the focus on improving the tribology of hydraulic reciprocating seals will enhance performance and longevity, ultimately driving efficiency across sectors such as oil, gas, and aviation.

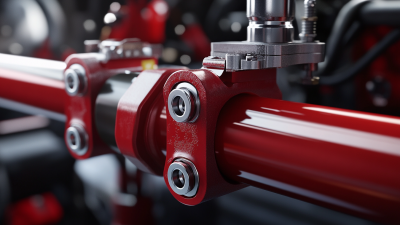

Choosing the Right Hydraulic Seal for Maximum Efficiency

Choosing the right hydraulic seal is crucial for ensuring max efficiency in industrial applications. Hydraulic seals play a vital role in preventing leaks and maintaining pressure within hydraulic systems. When selecting a hydraulic seal, consider factors such as the type of fluid, temperature ranges, and pressure ratings. It's essential to match the seal material with the operational environment to prolong its lifespan and enhance performance.

Tips: Always evaluate your application requirements before making a choice. For example, if you are working with high-temperature fluids, opt for seals made from heat-resistant materials like fluorocarbon or polyacrylate. Additionally, be mindful of the seal's design; a well-designed seal can reduce friction and wear, leading to improved efficiency.

Another critical factor is the installation process. Ensure that the seals are installed correctly to prevent premature failure. Take time to clean the sealing area thoroughly and follow manufacturer guidelines. Tips: Always use proper tools and techniques during installation to avoid damaging the seal. Regular inspections can also help identify potential issues before they escalate, contributing to a smoother operation in your hydraulic systems.

Common Challenges in Hydraulic Seal Performance and Solutions

In industrial applications, hydraulic seals play a pivotal role in ensuring system efficiency and longevity. However, these seals often face performance challenges, particularly in high-pressure environments and with the advent of next-generation biodegradable hydraulic fluids. As industries move towards more sustainable practices, the formulation of these fluids must meet strict performance metrics while maintaining compatibility with existing sealing materials. This evolution presents a unique set of challenges, as traditional seals may not perform optimally with these newer fluid types.

One major challenge in hydraulic seal performance is friction management, which can lead to increased wear and decreased efficiency. Innovative solutions are being explored to enhance seal designs, focusing on reducing friction without compromising sealing effectiveness. Additionally, as regulations surrounding materials like PFAS evolve, manufacturers must adapt their designs to comply with new guidelines while still addressing the demands of modern fluid power systems. By staying ahead of these challenges, companies can ensure that their sealing solutions not only meet current performance standards but also continue to enhance operational efficiency in an ever-evolving industrial landscape.

Emerging Trends in Hydraulic Seal Technology for Future Applications

Emerging trends in hydraulic seal technology are significantly shaping the future of industrial applications. As industries strive for greater efficiency and sustainability, innovations such as advanced materials and design methodologies are enhancing seal performance. According to a recent market report by Fortune Business Insights, the hydraulic seal market is projected to reach $11.2 billion by 2026, growing at a CAGR of 4.5% from 2019. This growth is primarily driven by the increasing demand for equipment reliability and energy-efficient solutions.

One of the most notable trends is the adoption of high-performance polymers and elastomers that can withstand higher pressures and temperatures. Materials such as fluoropolymers are being implemented for their exceptional chemical resistance, which extends the service life of hydraulic seals in challenging environments.

Furthermore, the integration of smart technologies, such as IoT sensors, is optimizing seal maintenance by providing real-time data on wear and tear, thereby reducing failure rates. A report from Research and Markets highlights that these smart seals can decrease maintenance costs by up to 30%, underscoring the trend towards intelligent industrial solutions. The future of hydraulic seals is not just about functionality; it's increasingly about efficiency and technological advancement.

Related Posts

-

How to Choose the Right Hydraulic Cylinder Seals for Optimal Performance

-

The Path Ahead for Hydraulic Seals in a Rapidly Evolving Market

-

Top Strategies for Sourcing High Quality Hyd Cylinder Repair Services

-

The Future of Hydraulic Piston Repair Innovations Shaping the Industry Beyond 2025

-

Unlocking Efficiency: Essential Insights for Sourcing High-Performance Hydraulic Rams Globally

-

Exploring Diverse Features and Applications of the Best New Hydraulic Cylinder Models